Umshini Wokubhoboza we-PLD3030A kanye ne-PLD4030 Gantry Mobile CNC

| Iigama le-tem | Ipharamitha | ||

| I-PLD3030A | I-PLD4030 | ||

| Ubuningi bokusebenza ngomshiniipuletiusayizi | Ubude x Ububanzi | 3000x3000mm | 4000*3000mm |

| Ubukhulu | 200mm | 100mm | |

| Umsebenziitafula | Ubukhulu bobubanzi bomsele ongu-T | 22mm | |

| Ikhanda lamandla okubhoboza | Qubuzwe | 2 | 1 |

| Ukubhoboza okuphezuluumgodiububanzi | Φ12mm-Φ50mm | ||

| I-RPM(ukuguqulwa kwemvamisa) | 120-450r/min | ||

| I-Morse taper ye-spindle | CHA. 4 | ||

| Amandla enjini ye-spindle | 2x7.5kW | 5.5KW | |

| Ibanga ukusuka ebusweni obungezansi be-i-spindleetafuleni lokusebenza | 200-550mm | ||

| Ukunyakaza kwe-gantry longitudinal (X-axis) | Ukuhamba kwe-X-axis | 3000mm | |

| Isivinini sokuhamba se-X-axis | 0-8m/min | ||

| Amandla enjini ye-servo ye-X-axis | 2x2.0kW | ||

| Ukunemba kokubeka i-X-axis | 0.1mm/Konke | ||

| Ukunyakaza kwekhanda lamandla eceleni (I-Y-axis) | Ibanga eliphezulu phakathi kwamakhanda amabili wamandla e-Y axis | 3000mm | |

| Ibanga elincane phakathi kwamakhanda amabili wamandla e-Y axis | 470mm | ||

| Amandla enjini ye-servo ye-Y-axis | 1.5KW | ||

| Ukunyakaza kokuphakelayo kwekhanda lamandla | Ukuhamba kwe-Z-axis | 350mm | |

| Amandla enjini ye-servo ye-Z-axis | 2*2KW | ||

| Ukuthutha nokupholisa ama-chip | Amandla enjini yokuhambisa i-chip | 0.75KW | |

| Amandla enjini yepompo yokupholisa | 0.45KW | ||

| Euhlelo lwegesi | Amandla enjini ephelele | Cishe i-30kW | Mayelana20kW |

| Ubukhulu obuphelele bethuluzi lomshini | Cishe ngo-6970x6035x2990mm | ||

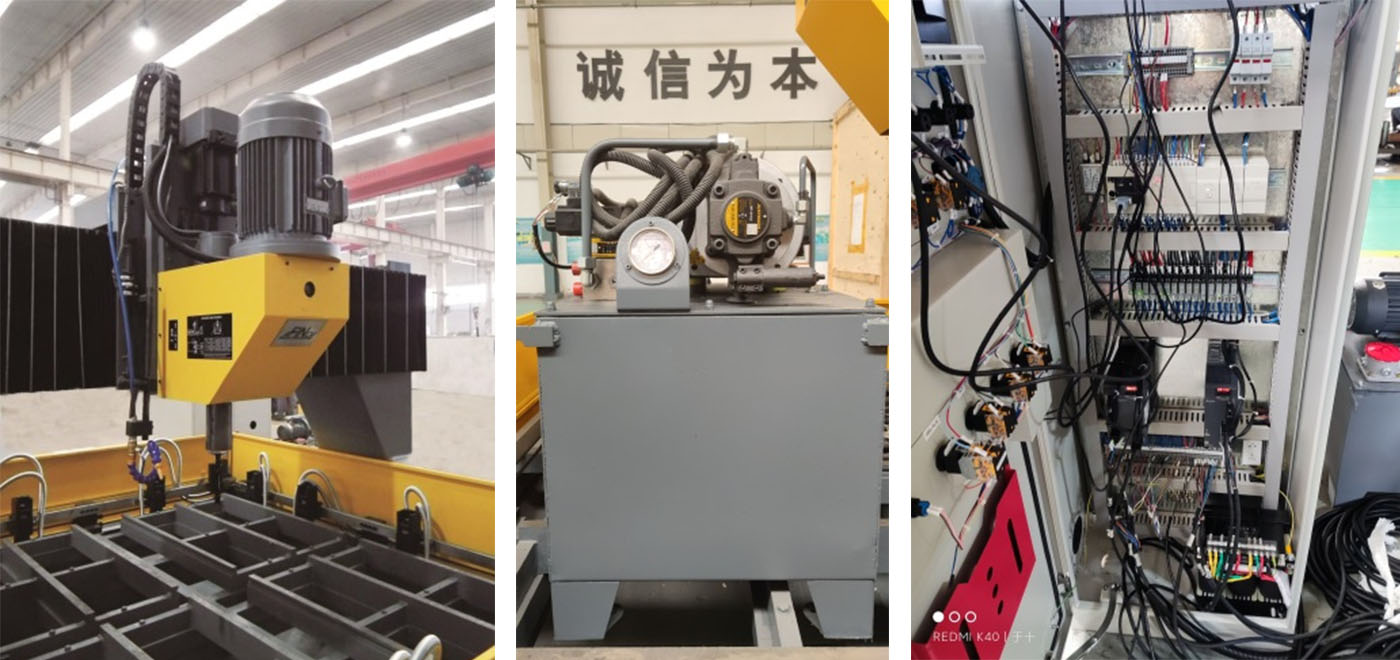

1. Ububanzi obukhulu bokubhoboza bethuluzi lomshini bungu-50mm, ubukhulu obukhulu bepuleti lokubhoboza bungu-200mm, kanti usayizi omkhulu wepuleti ungu-3000x3000mm.

2. Ithuluzi lomshini lihlonyiswe ngamakhanda amabili azimele okubhoboza amaslayidi okuphakelayo kwe-servo.

3. Indawo yokuxhumanisa yomgodi ingafakwa ngokushesha ngesivinini esingu-8m / min, futhi isikhathi esisekelayo sifushane kakhulu.

4. Injini ye-spindle yekhanda lamandla okubhoboza isebenzisa umthethonqubo wejubane lokuguqulwa kwemvamisa engenasinyathelo, kanti ijubane lokuphakelayo lisebenzisa umthethonqubo wejubane elingenasinyathelo se-servo, okulula ukuyisebenzisa.

5. Ngemva kokuthi ukubhoboza kusetshenziswe, kunomsebenzi wokulawula okuzenzakalelayo.

6. Imbobo ethambile ye-spindle yi-Morse No. 4, futhi ifakwe i-Morse No. 4/3 reducer sleeve, engafaka ama-drill bits anobubanzi obuhlukene.

7. Isakhiwo esiphathwayo se-gantry siyasetshenziswa, umshini umboza indawo encane futhi ukwakheka kwesakhiwo kuyafaneleka.

8. Ukunyakaza kwe-X-axis ye-gantry kusebenzisa isiqondiso se-linear rolling rail pair esinomthamo ophezulu wokuthwala, esiguquguqukayo.

9. Umshini ufakwe idivayisi yokusetha amathuluzi esiphethulo, engabona kalula indawo yepuleti.

10. Uhlelo lokulawula lusebenzisa isofthiwe ephezulu yokuhlela amakhompyutha ethuthukiswe ngokuzimela yinkampani yethu futhi ifaniswe nesilawuli esihleliwe se-PLC, esinezinga eliphezulu lokuzenzakalela.

11. Isitimela somhlahlandlela womshini kanye ne-lead screw nut kufakwe idivayisi yokuthambisa ezenzakalelayo.

12. Isitimela esiqondisa i-X-axis sisebenzisa isembozo esivikelayo sensimbi engagqwali, izinhlangothi zombili zesitimela esiqondisa i-y-axis sisebenzisa isembozo esivikelayo esiguquguqukayo, futhi i-baffle engangeni manzi yengezwa eduze kwebhentshi lokusebenza.

| CHA. | Igama | Umkhiqizo | Izwe |

| 1 | Lisitimela sokuqondisa esingahambi kahle | I-HIWIN/PMI | I-Taiwan, iShayina |

| 2 | Umshayeli we-Servo | I-Mitsubishi | I-Japan |

| 3 | Sinjini ye-ervo | I-Mitsubishi | I-Japan |

| 4 | Isilawuli esingahlelwa | I-Mitsubishi | I-Japan |

| 5 | Idivayisi yokuthambisa ezenzakalelayo | I-BIJUR/HERG | I-USA / Japan |

| 6 | Cikhompyutha | I-Lenovo | IShayina |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba