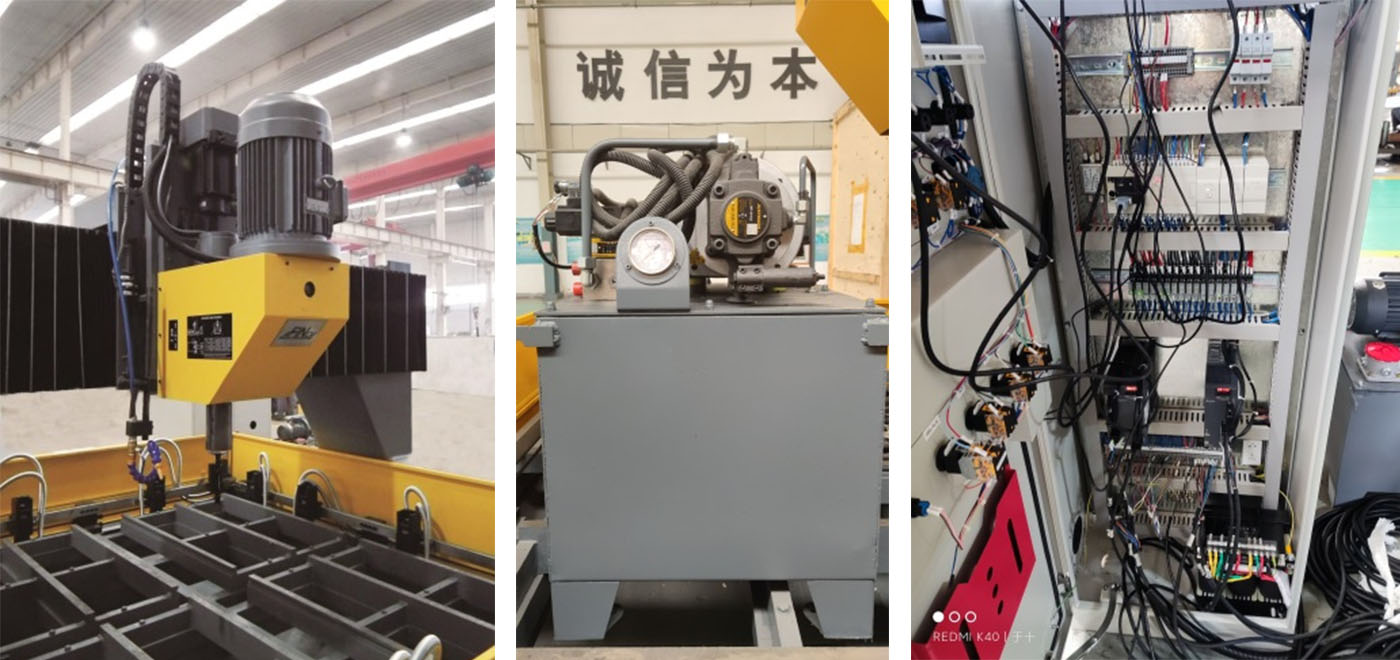

Umshini Wokubhoboza Amapuleti e-CNC e-Gantry Mobile we-PLD7030-2

| Ubuningiipuletiusayizi | Ubude x ububanzi | 7000x3000mm |

| Tukucasuka | 200mm | |

| Ithebula lomsebenzi | Usayizi we-T-groove | 22mm |

| Ikhanda lamandla okubhoboza | Ubuningi | 2 |

| Ukubhobozaumgodiububanzi bobubanzi | Φ12-Φ50mm | |

| I-RPM(imvamisa eguquguqukayo) | 120-560r/min | |

| I-Morse taper ye-spindle | Inombolo 4 | |

| Amandla enjini ye-spindle | 2X7.5kW | |

| Ukunyakaza kwe-gantry longitudinal (x-axis) | Ukushaya kwe-X-axis | 10000mm |

| Isivinini sokuhamba se-X-axis | 0-8m/min | |

| Amandla enjini ye-servo ye-X-axis | 2x2.0kW | |

| Ukunyakaza kwekhanda lamandla eceleni (I-Y-axis) | Ukuhamba nge-Y-axis | 3000mm |

| Isivinini sokuhamba se-Y-axis | 0-8m/min | |

| Amandla enjini ye-servo ye-Y-axis | 2X1.5kW | |

| Ukunyakaza kokuphakelwa kwekhanda lamandla (I-axis ka-Z) | I-stroke ye-Z-axis | 350mm |

| Izinga lokuphakelayo le-Z-axis | 0-4000mm/min | |

| Amandla enjini ye-servo ye-Z-axis | 2X1.5kW | |

| Ukuthutha nokupholisa ama-chip | Amandla enjini yokuhambisa i-chip | 0.75kW |

| Amandla enjini yepompo yokupholisa | 0.45kW | |

| Euhlelo lwegesi | Uhlelo lokulawula | PLC+ ikhompyutha ephezulu |

| Inani lama-axes e-CNC | 4 |

1. Indawo yokuxhumanisa yomgodi ingavela ngokushesha ngesivinini esingu-8m/min, kanti isikhathi esisekelayo sifushane kakhulu.

2. Umshini ufakwe ikhanda lamandla okubhoboza elishelelayo letafula le-servo feed. Injini ye-spindle yekhanda lamandla okubhoboza isebenzisa ukulawulwa kwesivinini semvamisa eguquguqukayo engenasinyathelo, kanti ijubane lokuphakela lisebenzisa ukulawulwa kwesivinini se-servo engenasinyathelo, okulula ukusebenza.

3. Ngemva kokuthi ukubhoboza kusetshenziswe, kunomsebenzi wokulawula okuzenzakalelayo.

4. Imbobo ethambile ye-spindle yi-Morse No.4 futhi ifakwe i-Morse no.4/3 reducing sleeve, engasetshenziswa ukufaka ama-drill bits anobubanzi obuhlukene.

5. Isakhiwo esiphathwayo se-gantry siyasetshenziswa, umshini umboza indawo encane futhi ukwakheka kwesakhiwo kuyafaneleka.

6. Ukunyakaza kwe-X-axis ye-gantry kuqondiswa amabhangqa amabili okuqondisa aqondile anomthamo ophezulu wokuthwala, aguquguqukayo.

7. Ukunyakaza kwe-Y-axis kwesihlalo esishelelayo sekhanda lamandla kuqondiswa amabhangqa amabili okuqondisa aqondile, futhi kuqhutshwa yi-AC servo motor kanye ne-precision ball screw pair, okuqinisekisa ukunemba okuphezulu kwendawo yokubhoboza.

9. Umshini ufakwe idivayisi yokusetha amathuluzi esikhungo sentwasahlobo, enganquma kalula indawo ye-flange.

10. Ifakwe i-chip remover kanye nethangi lokupholisa. Iphampu yokupholisa ijikeleza i-coolant yokubhoboza i-spindle ukuze ithuthukise ukusebenza kokubhoboza kanye nempilo yenkonzo yebhoboza.

11. Uhlelo lokulawula lusebenzisa i-PLC futhi luhlonyiswe ngekhompyutha ephezulu ukuze kube lula ukugcina nokufaka uhlelo lokucubungula amapuleti, futhi ukusebenza kulula. Ipulatifomu yesofthiwe iyisistimu yefasitela, ene-interface yokusebenza enobungane, ukuphathwa kwezinsiza okucacile nokusebenzayo, kanye nomsebenzi wokuhlela onamandla; usayizi wepuleti ungafakwa ngekhibhodi ngesandla noma ufakwe nge-interface ye-U-disk.

| CHA. | Igama | Umkhiqizo | Izwe |

| 1 | Lisitimela sokuqondisa esingahambi kahle | I-HIWIN/CSK | I-Taiwan, iShayina |

| 2 | I-PLC | I-Mitsubishi | I-Japan |

| 3 | Injini ye-Servo kanye nomshayeli | I-Mitsubishi | I-Japan |

| 4 | Iketanga lokuhudula | I-JFLO | IShayina |

| 5 | Inkinobho, isibani sesikhombisi | USchneider | IFrance |

| 6 | Isikulufu sebhola | I-PMI | I-Taiwan, iShayina |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba