Umshini wokubhoboza weselula we-PLM Series CNC Gantry

| Ii-tem | Name | ipharamitha | |||

| PLM3030-2 | I-PLM4040-2 | I-PLM5050A-2 | I-PLM6060-2 | ||

| Ubuningi bokusebenza ngomshiniizintousayizi | Ubude x ububanzi | 3000*3000 mm | 4000×4000 mm | 5000×5000 mm | 5000×5000 mm |

| Ubukhulu obukhulu bepuleti elicutshunguliwe | 250 mm, Ingakhula ibe ngu-380mm | ||||

| Umsebenziitafula | Usayizi webhentshi lomsebenzi | 3500×3000 mm | 4500×4000 mm | 5500×4000 mm | 5500×4000 mm |

| Ububanzi be-groove engu-T | 28 mm | ||||

| Lukuthwala imithwalo | 3tama-ons/㎡ | ||||

| UkubhobozaI-Spindle | Ubuningiukubhobozaububanzi bembobo | φ60 mm | |||

| Isilinganiso esiphezuluUbude Bethuluzi vs. Ububanzi Bembobo | ≤10(I-1965)Umqhelei-carbideukubhoboza) | ||||

| I-SpindleI-RPM | 30-3000 r/min | ||||

| I-spindle taper | I-BT50 | ||||

| Amandla enjini ye-spindle | 2×22kW | ||||

| I-torque ephezulu ye-spindlen≤750r/min | 280Nm | ||||

| Ibanga ukusuka ebusweni obungezansi be-i-spindleetafuleni lokusebenza | 280—780 mm (I-1965)Lungisa ngokuya ngokuthiizintoukujiya) | ||||

| Ukunyakaza kwe-gantry longitudinal (x-axis) | Ukushaya okuphezulu | 3000 mm | 4000 mm | 5000 mm | |

| Isivinini sokuhamba se-X-axis | 0—8m/min | ||||

| Amandla enjini ye-servo ye-X-axis | 2×2.7kW | ||||

| Pukunemba kokubekwa | I-X-axis、I-Y-axis | 0.06mm/ konkeisifo sohlangothi | 0.08mm/ konkeisifo sohlangothi | 0.10mm/ konkeisifo sohlangothi | |

| Ukunemba kokubeka okuphindayo | I-X-axis、I-Y-axis | 0.035mm/ konkeisifo sohlangothi | 0.04mm/ konkeisifo sohlangothi | 0.05mm/ konkeisifo sohlangothi | |

| Uhlelo lwe-hydraulic | Ukucindezela/ukugeleza kwephampu ye-hydraulic | 15MPa /25L/min | |||

| Amandla enjini yepompo ye-hydraulic | 3.0 kW | ||||

| Uhlelo lomoya | Umfutho wokunikezwa komoya | 0.5 Mpa | |||

| Ukususwa nokupholisa ama-chip | Uhlobo lokuthutha lwe-chip | Iketanga eliyisicaba | |||

| Inombolo ye-chip conveyor | 2 | ||||

| Isivinini sokususa ama-chip | 1m/umzuzu | ||||

| Amandla enjini yokuhambisa i-chip | 2×0.75kW | ||||

| Imodi yokupholisa | Ukupholisa kwangaphakathi + ukupholisa kwangaphandle | ||||

| Ingcindezi ephezulu | 2MPa | ||||

| Ukugeleza okuphezulu | 2×50L/min | ||||

| Uhlelo lukagesi | I-CNC | I-Siemens 828D | |||

| I-CNCi-axisInombolo | 6 | ||||

| Amandla enjini ephelele | Cishe 75kW | ||||

| Ubukhulu obuphelele bethuluzi lomshini | Ubude× Ububanzi × Okuphezulu | Mayelana 8m×8m×3m | Mayelana9m×9m×3m | Mayelana10m×10m×3m | Mayelana10m×10m×3m |

| Isisindo esiphelele sethuluzi lomshini | Cishe ama-32t | Mayelana40t | Mayelana48t | ||

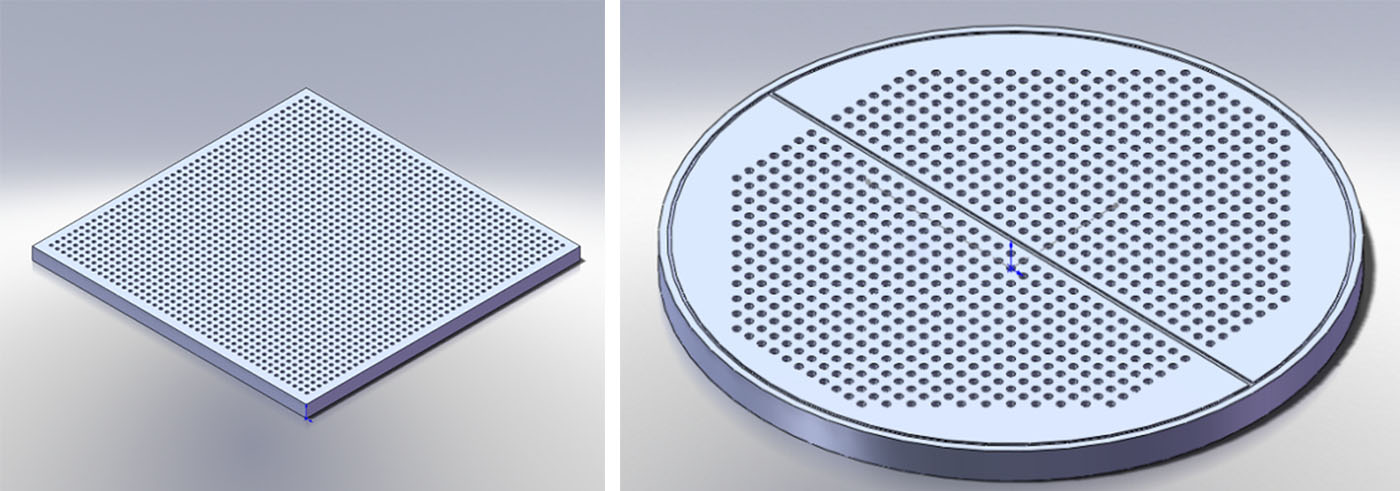

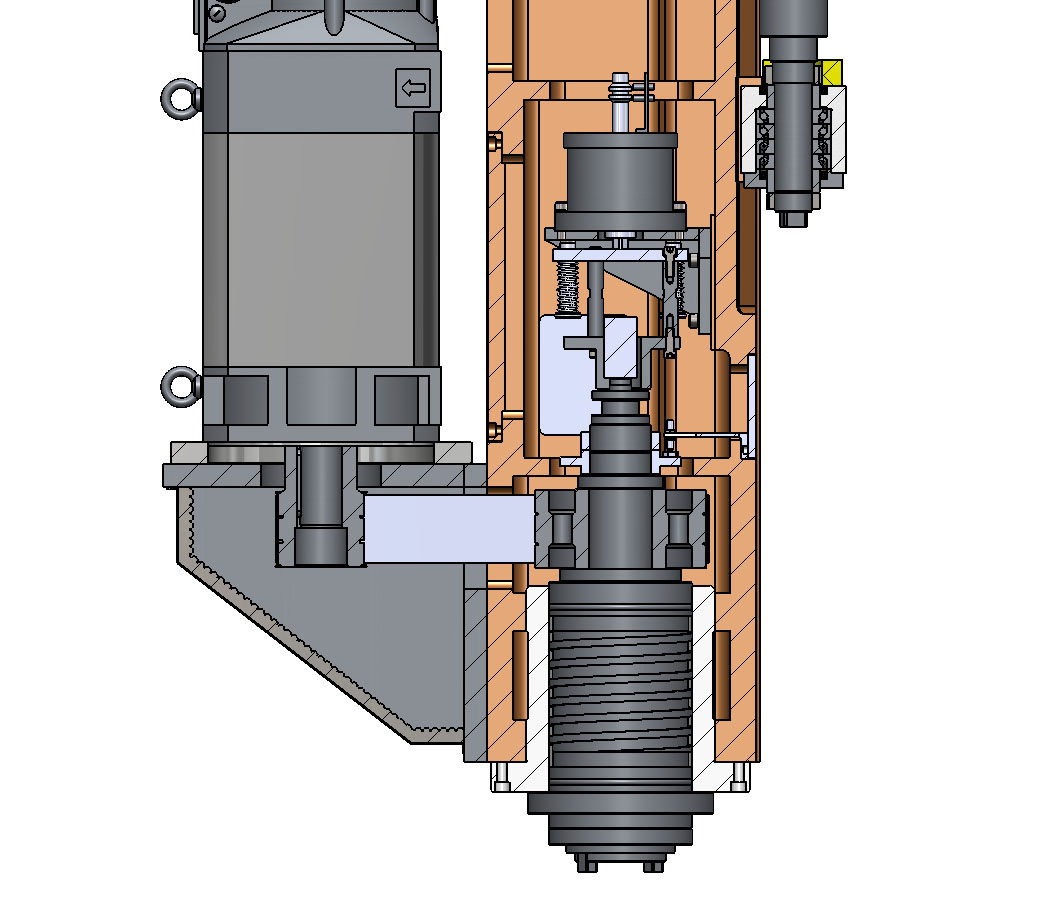

1. Lo mshini wakhiwe kakhulu ngombhede nekholomu, ugongolo kanye netafula elishelelayo elivundlile, ibhokisi lamandla okubhoboza uhlobo lwe-ram oluqondile, itafula lokusebenza, i-chip conveyor, uhlelo lwe-hydraulic, uhlelo lwe-pneumatic, uhlelo lokupholisa, uhlelo lokugcoba oluphakathi, uhlelo lukagesi, njll.

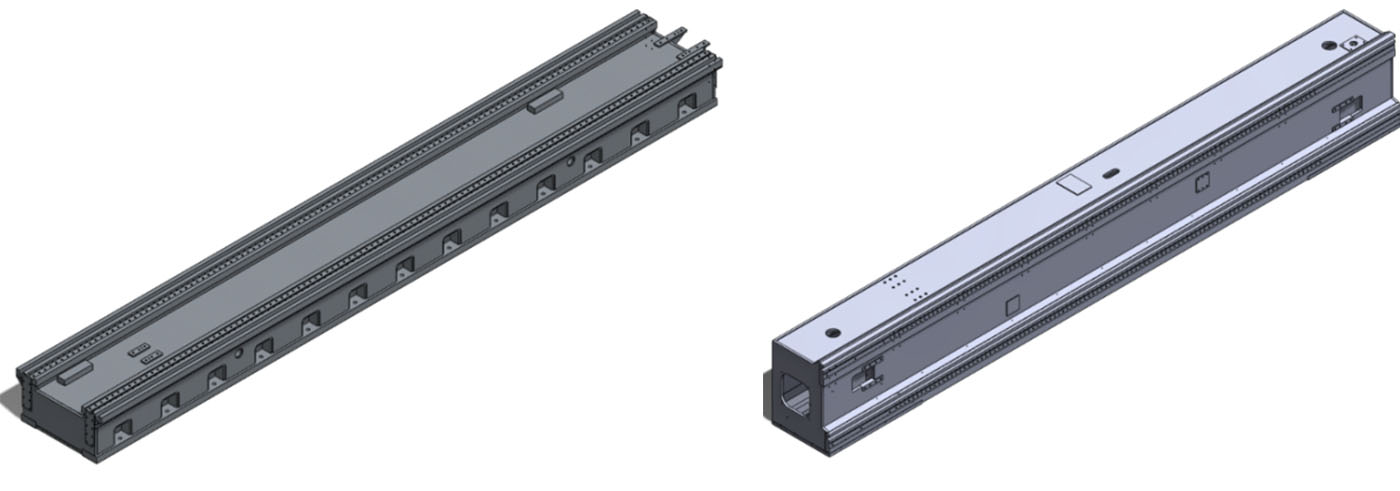

2. Isisekelo sokuthwala esiqinile kakhulu, ibhereyi isebenzisa ibhereyi ekhethekile yesikulufu esinokunemba okuphezulu. Ubuso besisekelo sokufaka obude kakhulu buqinisekisa ukuqina kwe-axial. Ibhereyi iqiniswa kusengaphambili yi-lock nut, kanti isikulufu sokuletha siqiniswa kusengaphambili. Inani lokwelula linqunywa ngokuya ngokuguquguquka kokushisa kanye nokwelulwa kwesikulufu sokuletha ukuqinisekisa ukuthi ukunemba kokubekwa kwesikulufu sokuletha akushintshi ngemva kokwenyuka kwezinga lokushisa.

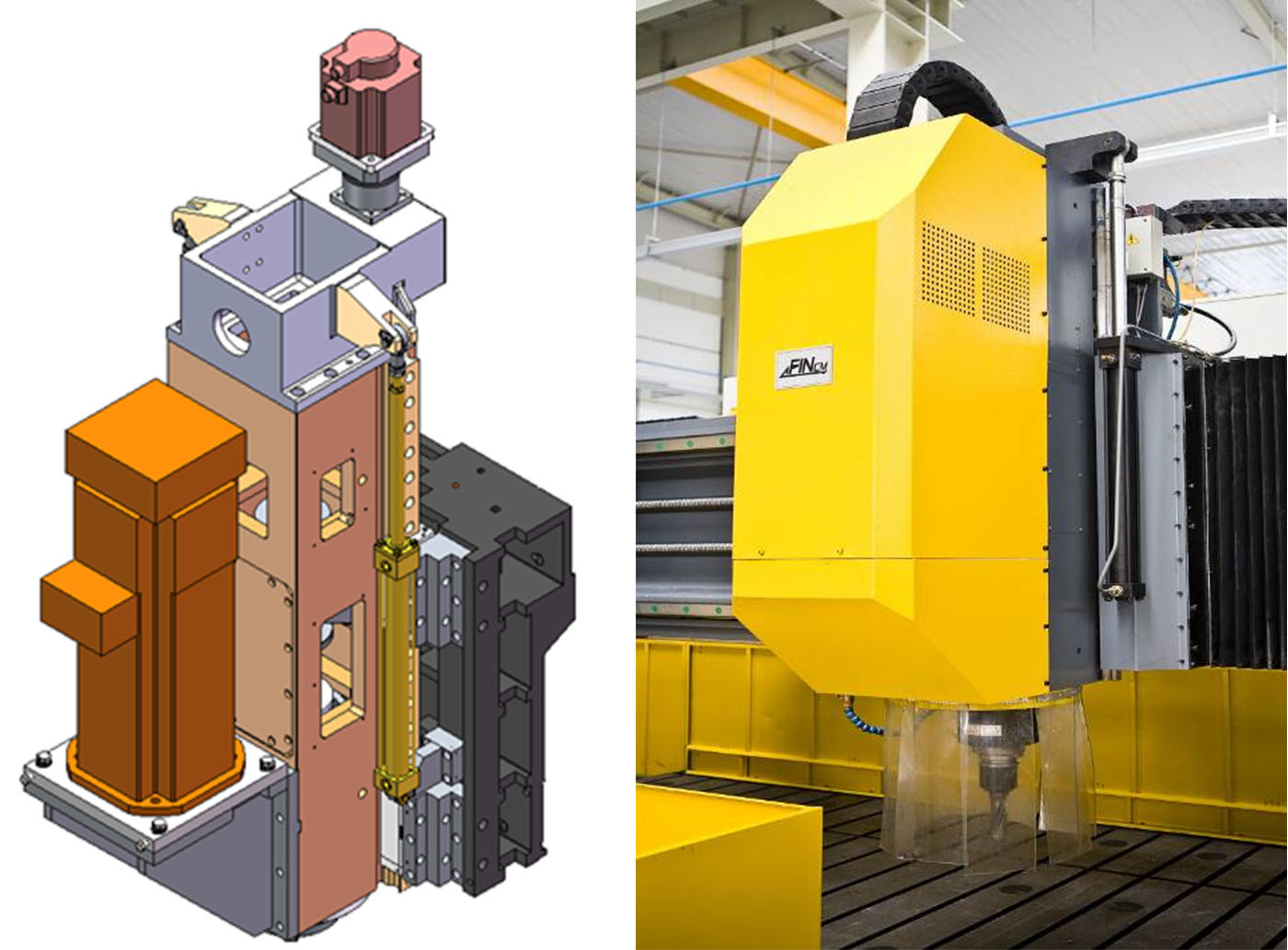

Ikhanda lamandla okubhoboza nokugaya

3. Ukunyakaza okuqondile (i-Z-axis) kwekhanda lamandla kuqondiswa yiziqondiso ezimbili eziqondile ezihleliwe ku-ram, ngokunemba okuhle komhlahlandlela, ukumelana nokudlidliza okuphezulu kanye ne-coefficient ephansi yokungqubuzana. Idrayivu yesikulufu sebhola iqhutshwa yi-servo motor nge-precision planetary reducer, enamandla aphezulu okuphakelayo.

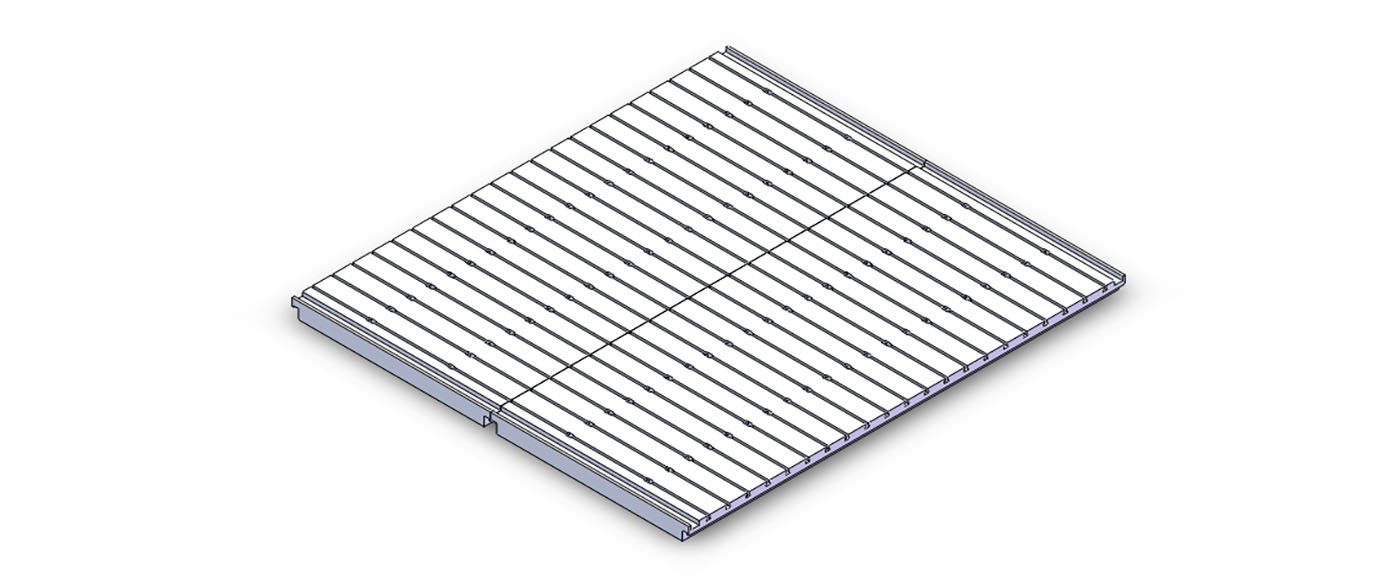

4. Lo mshini usebenzisa ama-chip conveyor amabili ayisicaba ezinhlangothini zombili zetafula lokusebenza. Ama-chip ensimbi kanye ne-coolant kuqoqwa ku-chip conveyor, bese ama-chip ensimbi athuthwa aye ku-chip conveyor, okulula kakhulu ukususwa kwama-chip; i-coolant iyasetshenziswa kabusha.

5. Lo mshini unikeza izindlela ezimbili zokupholisa—ukupholisa kwangaphakathi kanye nokupholisa kwangaphandle, okunikeza ukuthambisa okwanele kanye nokupholisa ithuluzi kanyeizintongesikhathi sokusika ama-chip, okuqinisekisa kangconoukubhobozaikhwalithi yokupholisa. Ibhokisi lokupholisa lihlonyiswe ngokutholwa kwezinga loketshezi kanye nezingxenye ze-alamu, kanti ingcindezi ejwayelekile yokupholisa ingu-2MPa.

I-spindle eqondile

6. Izitimela zokuqondisa ze-X-axis ezinhlangothini zombili zomshini zifakwe izembozo zokuvikela zensimbi engagqwali, kanti izitimela zokuqondisa ze-Y-axis zifakwe izembozo zokuvikela eziguquguqukayo kuzo zombili izinhlangothi.

Umthuthi we-chip

Idivayisi yokupholisa

Idivayisi yokuthambisa ezenzakalelayo

7. Lo mshini uphinde ufakwe umshini wokuthola umkhawulo we-photoelectric ukuze kube lula ukubeka ipuleti eliyindilinga.

Uhlelo lwe-Siemens CNC

| CHA. | Igama | Umkhiqizo | Izwe |

| 1 | Isitimela sokuqondisa esiqondile | I-HIWIN noma i-PMI | I-Taiwan, iShayina |

| 2 | Uhlelo Lokulawula lwe-CNC | I-Siemens | IJalimane |

| 3 | Injini ye-Servo kanye nomshayeli | I-Siemens | IJalimane |

| 4 | I-spindle eqondile | I-KENTURN noma i-SPINTECH | I-Taiwan, iShayina |

| 5 | I-valve ye-hydraulic | I-YUKEN noma i-Justmark | I-Japan |

| 6 | Iphampu kawoyela | I-Justmark | I-Taiwan, iShayina |

| 7 | Uhlelo lokuthambisa oluzenzakalelayo | I-BIJUR noma i-HERG | I-USA noma i-Japan |

| 8 | Izinkinobho, izibani zezinkomba kanye nezinye izingxenye zikagesi eziyinhloko | SCHBEIDER/ABB | IFrance/iJalimane |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba