Umshini Wokubhoboza Amapuleti E-CNC Ohambayo we-PLM4020 Gantry

(1) Umzimba wohlaka lomshini kanye nogongolo oluphambeneyo kufakwe ngesakhiwo esenziwe nge-welded, ngemuva kokwelashwa okushisa okuguga ngokwanele, ngokunemba okuhle kakhulu. Itafula lokusebenza, itafula elishelelayo elivundlile kanye ne-ram konke kwenziwe ngensimbi ephothiwe.

(2) Uhlelo lokushayela lwe-servo oluphindwe kabili olunezinhlangothi ezimbili ku-X axis luqinisekisa ukunyakaza okunembile kwe-gantry okuhambisanayo, kanye nobukhulu obuhle be-Y axis kanye ne-X axis.

(3) Ithebula lokusebenza lisebenzisa isimo esiqinile, insimbi ecijile esezingeni eliphezulu kanye nenqubo yokusika ethuthukisiwe, enomthamo omkhulu wokuthwala.

(4) Isihlalo sokuthwala esiqinile kakhulu, ibhereyi isebenzisa indlela yokufaka elandelanayo, ibhereyi ekhethekile enezikulufo ezinembile kakhulu.

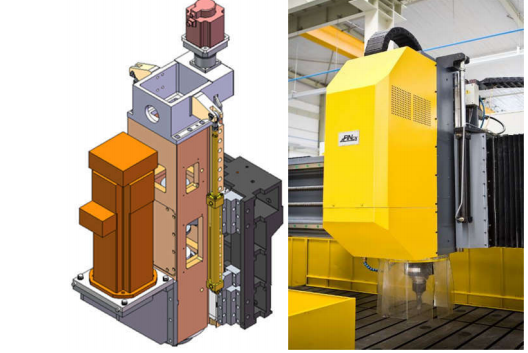

(5) Ukunyakaza okuqondile (i-Z-axis) kwekhanda lamandla kuqondiswa ama-roller linear guide pairs ahlelwe ezinhlangothini zombili ze-ram, enokunemba okuhle, ukumelana nokudlidliza okuphezulu kanye ne-friction coefficient ephansi.

(6) Ibhokisi lamandla okubhoboza lingelohlobo lwe-spindle oluqondile, olusebenzisa i-spindle yokupholisa yangaphakathi ye-Taiwan BT50. Umgodi we-spindle cone unedivayisi yokuhlanza, futhi ungasebenzisa i-drill yokupholisa yangaphakathi ye-carbide eqinisiwe, ngokunemba okuphezulu. I-spindle iqhutshwa yi-spindle servo motor enamandla amakhulu ngebhande elihambisanayo, isilinganiso sokunciphisa singu-2.0, isivinini se-spindle singu-30~3000r/min, futhi ububanzi besivinini bubanzi.

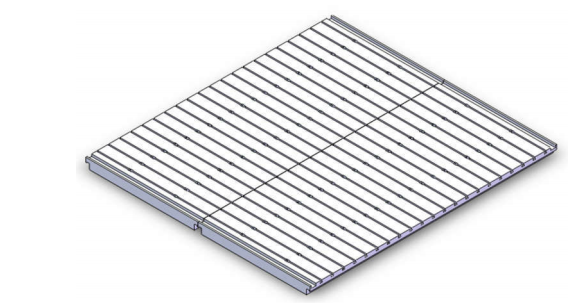

(7) Umshini usebenzisa ama-chip remover amabili ayisicaba ezinhlangothini zombili zetafula lokusebenza. Ama-chip ensimbi kanye ne-coolant kuqoqwa ku-chip remover. Ama-chip ensimbi athuthwa aye ku-chip carrier, okulula kakhulu ukususwa kwama-chip. I-coolant iyasetshenziswa kabusha.

(8) Umshini unikeza izinhlobo ezimbili zezindlela zokupholisa - ukupholisa kwangaphakathi kanye nokupholisa kwangaphandle. Iphampu yamanzi enomfutho ophezulu isetshenziselwa ukuhlinzeka ngesibandisi esidingekayo sokupholisa kwangaphakathi, ngomfutho ophezulu kanye nokugeleza okukhulu.

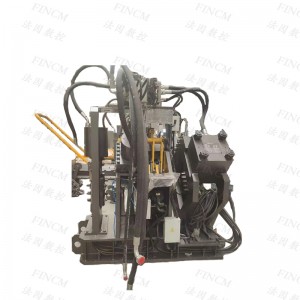

(9) Umshini ufakwe uhlelo lokuthambisa oluzenzakalelayo, olupompa uwoyela wokugcoba ungene kubhulokhi elishelelayo le-linear guide pair, i-ball screw pair screw nut kanye ne-rolling bearing yengxenye ngayinye njalo ukuze kwenziwe ukuthambisa okwanele nokuthembekile.

(10) Izinsika zokuqondisa ze-X-axis ezinhlangothini zombili zomshini zifakwe izembozo zokuvikela zensimbi engagqwali, kanti izinsika zokuqondisa ze-Y-axis zifakwe izembozo zokuvikela eziguquguqukayo.

(11) Ithuluzi lomshini lifakwe ne-photoelectric edge finder ukuze kube lula ukubeka izingxenye zomsebenzi eziyindilinga.

(12) Ithuluzi lomshini liklanywe futhi lifakwe nezindawo zokuphepha eziphelele. Ugongolo lwe-gantry lufakwe ipulatifomu yokuhamba, i-guardrail, kanye nesitebhisi sokukhuphuka ohlangothini lwekholomu ukuqinisekisa ukuphepha kwabasebenzi bokusebenza nokulungisa. Isembozo se-PVC esithambile esibonakalayo sifakwe sizungeze umgodi oyinhloko.

(13) Uhlelo lwe-CNC luhlonyiswe nge-Siemens 808D noma i-Fagor 8055, enemisebenzi enamandla. I-interface yokusebenza inemisebenzi yengxoxo yomshini womuntu, isinxephezelo samaphutha kanye ne-alamu ezenzakalelayo. Uhlelo luhlonyiswe nge-electronic handwheel, okulula ukuyisebenzisa. Luhlonyiswe ngekhompyutha ephathekayo, uhlelo oluzenzakalelayo lwe-CAD-CAM lungabonakala ngemva kokufakwa kwesofthiwe yekhompyutha ephezulu.

| Into | Igama | Inani |

|---|---|---|

| Usayizi Omkhulu Wepuleti | Ububanzi x Ububanzi | 4000×2000 mm |

| Usayizi Omkhulu Wepuleti | Ububanzi | Φ2000mm |

| Usayizi Omkhulu Wepuleti | Ubukhulu obukhulu | 200 mm |

| Ithebula Lomsebenzi | Ububanzi be-T Slot | 28 mm (ejwayelekile) |

| Ithebula Lomsebenzi | Ubukhulu bethebula lomsebenzi | 4500x2000mm (LxW) |

| Ithebula Lomsebenzi | Isisindo Sokulayisha | Amathani ama-3/㎡ |

| I-Spindle Yokubhoboza | Ububanzi Bokubhoboza Obukhulu | Φ60 mm |

| I-Spindle Yokubhoboza | Ububanzi obukhulu bokuthinta | I-M30 |

| I-Spindle Yokubhoboza | Ubude benduku ye-spindle yokubhoboza uma kuqhathaniswa nobubanzi bembobo | ≤10 |

| I-Spindle Yokubhoboza | I-RPM | 30~3000 r/min |

| I-Spindle Yokubhoboza | Uhlobo lwetheyiphu ye-Spindle | I-BT50 |

| I-Spindle Yokubhoboza | Amandla enjini ye-spindle | 22kW |

| I-Spindle Yokubhoboza | I-Torque Ephezulu (n≤750r/min) | 280Nm |

| I-Spindle Yokubhoboza | Ibanga ukusuka ebusweni obuphansi be-Spindle kuya etafuleni lokusebenza | 280 ~780 mm (ingalungiseka ngokobukhulu bezinto ezibonakalayo) |

| Ukunyakaza Kwe-Gantry Longitudinal (X Axis) | Uhambo Olukhulu | 4000 mm |

| Ukunyakaza Kwe-Gantry Longitudinal (X Axis) | Isivinini sokunyakaza nge-axis X | 0~10m/min |

| Ukunyakaza Kwe-Gantry Longitudinal (X Axis) | Amandla enjini ye-Servo ye-X axis | 2×2.5kW |

| Ukunyakaza Okuphambene Kwe-Spindle (Y Axis) | Uhambo Olukhulu | 2000mm |

| Ukunyakaza Okuphambene Kwe-Spindle (Y Axis) | Isivinini sokunyakaza nge-axis Y | 0~10m/min |

| Ukunyakaza Okuphambene Kwe-Spindle (Y Axis) | Amandla enjini ye-Servo ye-Y axis | 1.5kW |

| Ukuhamba Kokuphakelayo Kwe-Spindle (Z Axis) | Uhambo Olukhulu | 500 mm |

| Ukuhamba Kokuphakelayo Kwe-Spindle (Z Axis) | Isivinini sokudla se-axis Z | 0~5m/min |

| Ukuhamba Kokuphakelayo Kwe-Spindle (Z Axis) | Amandla enjini ye-Servo ye-axis ye-Z | 2kW |

| Ukunemba kokubeka | I-axis X, i-axis Y | 0.08/0.05mm/uhambo oluphelele |

| Ukunemba kokubekwa okuphindaphindwayo | I-axis X, i-axis Y | 0.04/0.025mm/uhambo oluphelele |

| Uhlelo lwe-hydraulic | Ingcindezi yepompo ye-hydraulic/Izinga lokugeleza | 15MPa /25L/min |

| Uhlelo lwe-hydraulic | Amandla enjini yepompo ye-hydraulic | 3.0kW |

| Uhlelo lomoya | Umfutho womoya ocindezelwe | 0.5 MPa |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Uhlobo lokususa izicucu | Uchungechunge lwepuleti |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Amanani okususa izicucu. | 2 |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Isivinini sokususa izicucu | 1m/umzuzu |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Amandla Emoto | 2×0.75kW |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Indlela yokupholisa | Ukupholisa kwangaphakathi + Ukupholisa kwangaphandle |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Ukucindezela Okuphezulu | 2MPa |

| Ukususwa kwezicucu kanye nohlelo lokupholisa | Izinga lokugeleza eliphezulu | 50L/umzuzu |

| Uhlelo lwe-elekthronikhi | Uhlelo lokulawula lwe-CNC | I-Siemens 808D |

| Uhlelo lwe-elekthronikhi | AmaNombolo e-CNC Axis | 4 |

| Uhlelo lwe-elekthronikhi | Amandla aphelele | Cishe i-35kW |

| Ubukhulu Obuphelele | L×W×H | Cishe 10×7×3m |

| Cha. | Igama | Umkhiqizo | Izwe |

|---|---|---|---|

| 1 | Isitimela sokuqondisa esiqondile se-roller | Hiwin | IShayina iTaiwan |

| 2 | Uhlelo lokulawula lwe-CNC | I-Siemens/ Fagor | IJalimane/iSpain |

| 3 | Ukondla i-servo motor kanye nomshayeli we-servo | I-Siemens/Panasonic | IJalimane/iJapani |

| 4 | I-spindle enembile | I-Spintech/Kenturn | IShayina iTaiwan |

| 5 | I-valve ye-hydraulic | Yuken/Justmark | IJapan/iShayina iTaiwan |

| 6 | Iphampu kawoyela | I-Justmark | IShayina iTaiwan |

| 7 | Uhlelo lokugcoba oluzenzakalelayo | I-Herg/BIJUR | IJapan/yaseMelika |

| 8 | Inkinobho, Isikhombisi, izingxenye ze-elekthronikhi eziphansi | I-ABB/Schneider | IJalimane/iFrance |

| Cha. | Igama | Usayizi | Ubuningi. |

|---|---|---|---|

| 1 | Isitholi somphetho we-Optical | Isiqephu esisodwa | |

| 2 | I-wrench yangaphakathi ye-hexagon | Isethi e-1 | |

| 3 | Isibambi samathuluzi kanye ne-stud yokudonsa | Φ40-BT50 | Isiqephu esisodwa |

| 4 | Isibambi samathuluzi kanye ne-stud yokudonsa | Φ20-BT50 | Isiqephu esisodwa |

| 5 | Upende ongeziwe | – | Ama-keg amabili |

1. Ukunikezwa kwamandla: isigaba 3 imigqa emi-5 380+10%V 50+1HZ

2. Umfutho womoya ocindezelwe: 0.5MPa

3. Izinga lokushisa: 0-40℃

4. Umswakama: ≤75%