Umshini Wokubhoboza we-PPL1255 CNC Wamapuleti Asetshenziselwa Imisebe Ye-Chassis Yeloli

| CHA. | IGAMA | IZINHLOBO | |

| 1 | Izinto zepuleti ze-chassis yeloli/iloli | Ipuletiubukhulu | Ubude:4000~12000mm |

| Ububanzi:250~550mm | |||

| Ubukhulu:4~12mm | |||

| Isisindo:≤600kg | |||

| Ububanzi be-punch:i-φ9~φ60mm | |||

| 2 | Umshini wokubhoboza we-CNC (i-Y axis) | Ukucindezela Okujwayelekile | 1200kN |

| Ubuningi be-punch die | 25 | ||

| I-axis engu-Yisifo sohlangothi | cishe u-630mm | ||

| Isivinini esiphezulu se-axis engu-Y | 30m/min | ||

| Amandla enjini ye-Servo | 11kW | ||

| Ibhulokhiisifo sohlangothi | 180mm | ||

| 3 | Iyunithi yokulayisha ene-magnetic | Ukuhamba kwezingaisifo sohlangothi | cishe 1800mm |

| Ukunyakaza okuqondileisifo sohlangothi | Cishe u-500mm | ||

| Amandla enjini asezingeni | 0.75kW | ||

| Amandla enjini aqondile | 2.2k | ||

| Ubuningi be-Magnetic | 10 ama-pcs | ||

| 4 | Iyunithi yokondla ye-CNC (i-X axis) | Ukuhamba kwe-X axis | Cishe i-14400mm |

| Isivinini esiphezulu se-axis X | 40m/min | ||

| Amandla enjini ye-Servo | 5.5kW | ||

| Ubuningi bokubopha nge-hydraulic | 7 ama-pcs | ||

| Amandla okubopha | 20kN | ||

| Ukuhamba kokuvula i-clamp | 50mm | ||

| Ukuhamba kokukhulisa i-clamp | Cishe 165mm | ||

| 5 | Ukondla umthuthi | Ukuphakama kokudla | 800mm |

| Ubude bokudla | ≤13000mm | ||

| Ubude bokudla ngaphandle | ≤13000mm | ||

| 6 | Iyunithi yokucindezela | Inanii-ity | Iqembu le-6 |

| Ukuhamba | cishe u-450mm | ||

| Phusha | 900N/ iqembu | ||

| 7 | Euhlelo lwegesi | Amandla aphelele | cishe ama-85kW |

| 8 | Umugqa wokukhiqiza | Ubude x ububanzi x ukuphakama | cishe 27000×8500×3400mm |

| Isisindo esiphelele | cishe ama-44000kg | ||

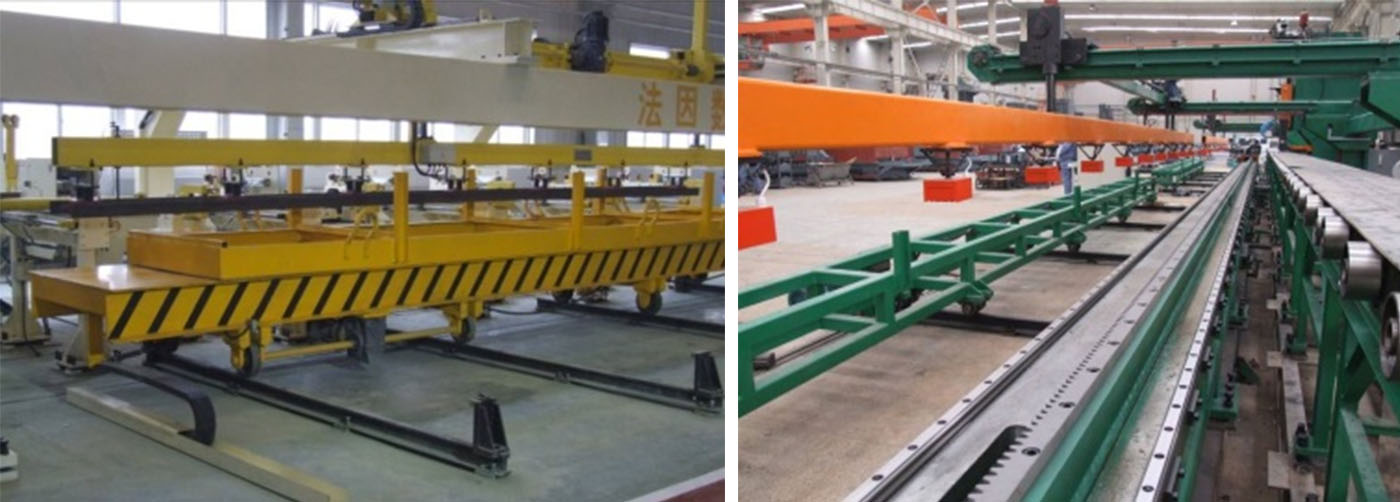

1. Ukusunduza ohlangothini, ukulinganisa ububanzi beshidi lensimbi kanye nendlela yokufaka phakathi ngokuzenzakalelayo: Lezi zindlela zinobuchwepheshe obunelungelo lobunikazi futhi zinokunemba okuphezulu kokulinganisa futhi zingezinzuzo zokufaka nokulungisa kalula, ishidi lensimbi lingabekwa eceleni kweshidi lensimbi.

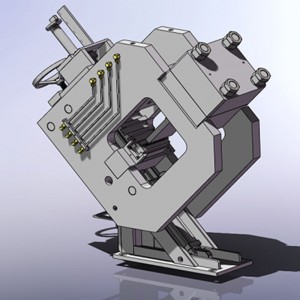

Iyunithi eyinhloko yokubhoboza: Umzimba womshini uwuhlaka oluvulekile lohlobo C, okulula ukulusevisa. Indlela yokucindezela i-hydraulic stripper kanye nendlela yokukhipha umthwalo we-punch zisebenza ndawonye ukugwema ukugoba kweshidi lensimbi, okuqinisekisa ukuphepha komshini.

3. Indlela yokushintsha ngokushesha i-punch kanye ne-die: Le ndlela yobuchwepheshe obunelungelo lobunikazi kanye ne-punch futhi ingashintshwa ngesikhathi esifushane kakhulu, ishintshwe ehlukile noma isethi yonke ngesikhathi.

| NO. | Igama | Umkhiqizo | Izwe |

| 1 | Isilinda esisebenza kabili | I-SMC/FESTO | IJapani / iJalimane |

| 2 | Isilinda sesikhwama somoya | I-FESTO | IJalimane |

| 3 | I-valve ye-solenoid kanye nokushintsha kwengcindezi, njll.. | I-SMC/FESTO | IJapani / iJalimane |

| 4 | Isilinda esiyinhloko sokubhoboza | IShayina | |

| 5 | Izingxenye eziyinhloko ze-hydraulic | I-ATOS | I-Italy |

| 6 | isitimela somhlahlandlela esiqondile | I-HIWIN/PMI | I-Taiwan, iShayina(I-axis engu-Y) |

| 7 | isitimela somhlahlandlela esiqondile | I-HIWIN/PMI | I-Taiwan, iShayina(I-X-axis) |

| 8 | Ukuhlanganiswa okunwebekayo ngaphandle kokubuyela emuva | I-KTR | IJalimane |

| 9 | I-Reducer, i-clearance removal gear kanye ne-rack | I-ATLANTA | IJalimane(I-X-axis) |

| 10 | Iketanga lokuhudula | I-Igus | IJalimane |

| 11 | Injini ye-Servo kanye nomshayeli | Yaskawa | I-Japan |

| 12 | Isiguquli semvamisa | I-Rexroth/ Siemens | IJalimane |

| 13 | I-CPU namamojula ahlukahlukene | I-Mitsubishi | I-Japan |

| 14 | Isikrini sokuthinta | I-Mitsubishi | I-Japan |

| 15 | Idivayisi yokuthambisa ezenzakalelayo | I-Herg | I-Japan(Uwoyela omncane) |

| 16 | Ikhompyutha | I-Lenovo | IShayina |

| 17 | Isiqandisi samafutha | I-Tofly | IShayina |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba