Umshini Wokubhoboza we-RDL25A CNC Wezitimela

| Ukucaciswa kwesitimela esicutshunguliwe | Uhlobo lwesitimela | 43Kg/m,50Kg/m,60Kg/m,75Kg/m,I-UIC54,I-UIC60 |

| ATimodeli yesitimela | 50AT,60 AT,I-UIC60D40 | |

| Isitimela sephiko lesigaba esikhethekile | 60TY | |

| Ububanzi bosayizi wesitimela | Ububanzi obungezansi | 114-152mm |

| Ukuphakama kwesitimela | 128-192mm | |

| Iwebhuukujiya | 14.5-44mm | |

| Ubude besitimela (ngemuva kokusikwa) | 6-25m | |

| Uhlobo lwezinto zesitimela | U71Mn σb≥90Kg/mm² HB250I-PD3 σb≥98Kg/mm² HB290-310 | |

| Ukubhobozaikhanda | Ububanzi | φ20~φ33 |

| Ibanga lobude | 3D~4D | |

| Izidingo zokucubungula | Ububanzi bokuphakama kwembobo | 35~100mm |

| Hi-oleububanzi izinombolokusitimela ngasinye | 1~4 izinhlobo | |

| Kuvunyelweukubekezelelanaisikhala sembobo esiseduze | ± 0.3mm | |

| Kuvunyelweukubekezelelanaphakathi kobuso besitimela kanye nebanga eliseduze lembobo | ± 0.5mm | |

| Kuvunyelweukubekezelelanaibanga elide kakhulu lesitimela | ± 0.5mm | |

| Kuvunyelweukubekezelelanakweububanzi bembobousayizi | 0~+0.3mm | |

| Ubulukhuni bodonga lwembobo | I-Ra12.5 | |

| Kuvunyelweukubekezelelanaukuphakama kwesikhungo sembobo (kusukela phansi kwesitimela) | ± 0.3mm | |

| Ikholomu yeselula (kufaka phakathi i-drillingibhokisi lamandla) | Ubuningi | Isethi e-1 |

| Umgodi we-spindle taper | I-BT50 | |

| Ububanzi besivinini se-spindle (ukulawulwa kwesivinini okungenazinyathelo) | 10~3200r/min | |

| Amandla enjini ye-Servo ye-Servo ye-Spindle | 37kW | |

| Ukuhamba kwesilayidi okuqondile (i-Y axis) | 800mm | |

| Amandla enjini ye-servo yeslayidi eqondile (Y-axis) | 3.1kw | |

| Ukushaywa kwesiphakeli sokubhoboza okuvundlile (i-axis ka-Z) | 350mm | |

| Amandla enjini ye-servo yokubhoboza evundlile (i-Z axis) | 3.1kw | |

| I-stroke yokuhamba evundlile yekholomu (i-axis X) | 25m | |

| Amandla enjini ye-servo motor yokunyakaza okuvundlile (X axis) | 3.1kw | |

| Isivinini esikhulu sokuhamba se-X-axis | 10m/min | |

| Isivinini esiphezulu sokuhamba se-axis Y, Z | 8m/min | |

| I-sucker kagesi ehlala njalo | Ubuningi | Isethi e-1 |

| Usayizi we-sucker (L × w × h) | 250×200×120mm | |

| Ukumunca okusebenzayo | ≥200N/cm² | |

| Isilinda sokusunduza eceleni | Ububanzi besilinda × ukushaya | Φ50×70mm |

| Ukucindezela ohlangothini lwesilinda esisodwa | 700Kg | |

| Itafula eliphakamisayo | Ubuningi | Isethi e-1 |

| Isivinini sokudlulisa | ≤15m/min | |

| Isilinda esisekelayo sokubamba phansi | Ubuningi | Isethi e-1 |

| Amandla okucindezela | ≥1500Kg/isethi | |

| Ukususwa kwe-chip | Uhlobo lokuthutha lwe-chip | Iketanga eliyisicaba |

| Isivinini sokususa ama-chip | 2m/umzuzu | |

| Amandla enjini yokususa ama-chip | 2.2kW | |

| Uhlelo lwe-hydraulic | Ubuningi | Amasethi ama-2 |

| Ingcindezi yepompo ye-hydraulic / ukugeleza / amandla | 6-6.5Mpa/25L/min/4kW Isethi e-1 | |

| Ingcindezi yepompo ye-hydraulic / ukugeleza / amandla | 5.5-6Mpa/66L/min/7.5kW 1 isethi | |

| Uhlelo lukagesi | Uhlelo lokulawula izinombolo | I-Siemens 828D |

| Inani lama-axes e-CNC | 5+1 | |

| Umthombo womoya | Ukucindezela komoya okucindezelwe | 0.6Mpa |

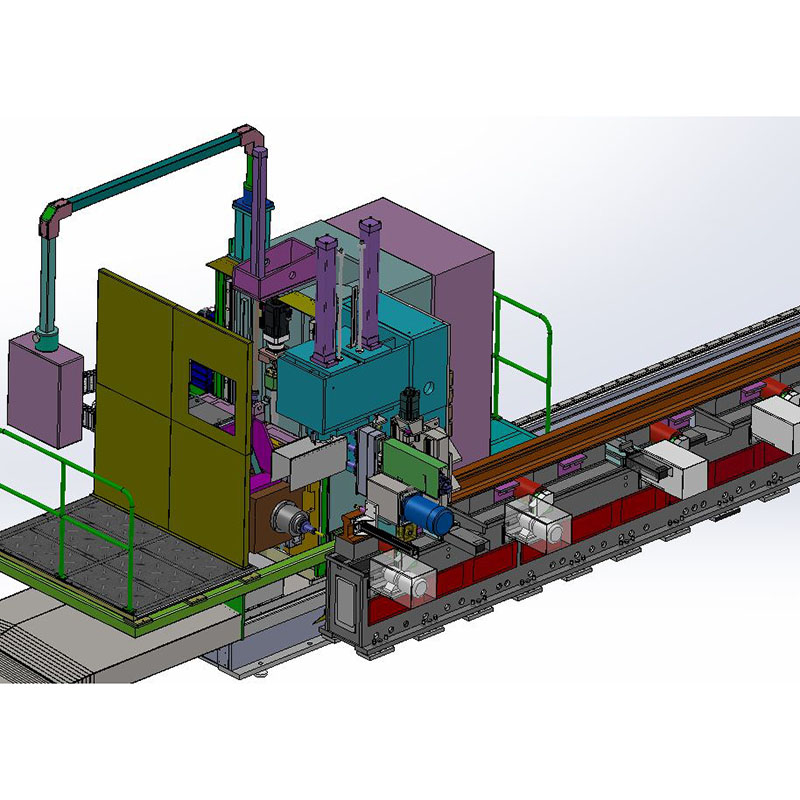

| Ubukhulu obuphelele | (L× W× H) | Cishe 57×8.7×3.8m |

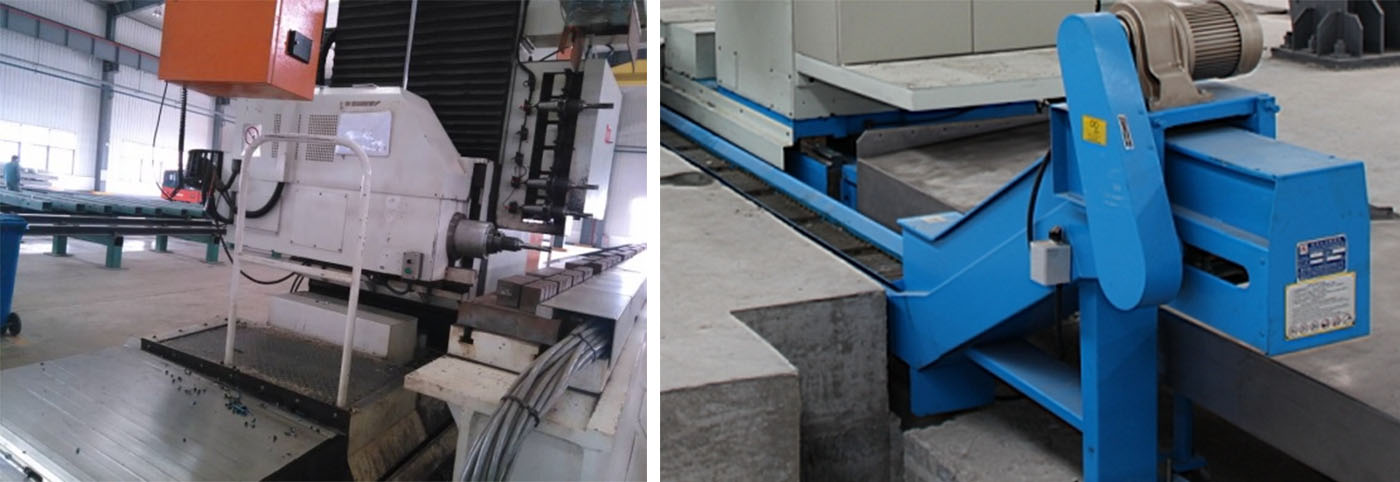

1. Umbhede womshini uhlukaniswe netafula lokusebenza, futhi umbhangqwana wesitimela esiqondisayo wombhede uhlelwe ngokuvundlile ukuze kwandiswe impilo yesevisi yombhangqwana wesitimela esiqondisayo; Isakhiwo sepuleti lensimbi elihlanganisiwe siyasetshenziswa, futhi ukunemba nokuzinza kuqinisekiswa ngokunamathisela, ukukhululeka ekucindezelekeni kanye nokwelashwa kokuguga okwenziwe.

2. Kufakwe i-chuck enamandla kagesi etafuleni lokusebenza lethuluzi lomshini ukuze kuqiniswe izinto. Naka ukuhleleka kusukela maphakathi kuya ezinhlangothini zombili lapho i-sucker kagesi ivaliwe, futhi naka ukuvala nokuvala amanzi.

3. Ikholomu yeselula isebenzisa isakhiwo sokushisela ipuleti lensimbi, esifakwe emanzini ukuze kususwe ukucindezeleka kanye nokwelashwa kokuguga okwenziwe ukuqinisekisa ukunemba okuzinzile.

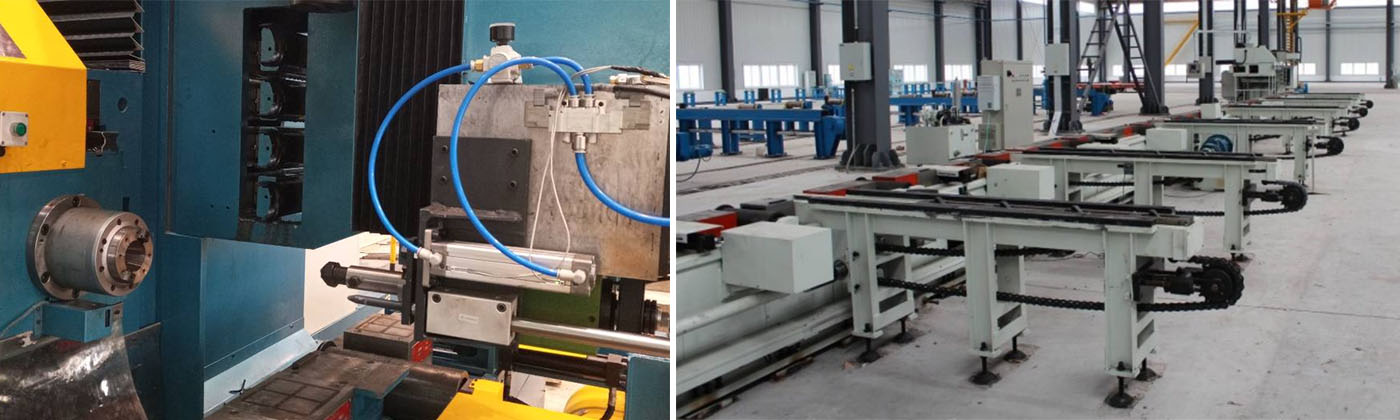

4. I-chain plate automatic chip remover iwuhlobo lwe-flat chain, futhi ifakwe phakathi kwetafula lokusebenza lombhede.

5. Umshini ufakwe iziteshi ezimbili ze-hydraulic, esinye sifakwe kukholomu yeselula, esetshenziswa kakhulu ukulinganisa isilinda, ukucindezela isilinda kanye nesilinda sommese; Esinye sifakwe esisekelweni, esisetshenziswa kakhulu ukuphakamisa isilinda kanye nokudonsa isilinda setafula elihambisayo eliphakamisayo.

6. Kunezimbazo ezintathu ze-CNC emshinini, ngayinye eqondiswa yi-precision linear rolling guide pair.

7. Ithuluzi lokubhoboza lisebenzisa i-index able carbide u drill, bese i-spindle ipholiswa yi-air inkungu.

8. Uhlelo lwe-Siemens 828D CNC lusetshenziswa ohlelweni lwe-CNC, olungaqapha inqubo yokubhoboza ngesikhathi sangempela.

| NO. | Igama | Umkhiqizo | Izwe |

| 1 | Ipheya lomhlahlandlela webhola | I-HIWIN/PMI | I-Taiwan (iShayina) |

| 2 | I-CNCuhlelo | I-Siemens 828D | IJalimane |

| 3 | Sinjini ye-ervo | I-Siemens | IJalimane |

| 4 | I-valve ye-hydraulic | I-ATOS | I-Italy |

| 5 | Iphampu kawoyela | I-Justmark | I-Taiwan (iShayina) |

| 6 | Iketanga lokuhudula | II-GUS/CPS | IJalimane / iKorea |

| 7 | Injini ye-servo ye-spindle | I-Siemens | IJalimane |

| 8 | Isinciphisi | I-ATLANTA | IJalimane |

| 9 | I-spindle eqondile | I-Kenturn | I-Taiwan (iShayina) |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba