Umugqa Wokukhiqiza Ohlanganisiwe We-RDS13 CNC Wokusaha Nokubhoboza

| Into | ipharamitha | Imininingwane |

| Imodeli yesitimela eyisisekelo | Uhlobo lwezinto | 50Kg/m,60 kg/m,75 kg/m ubulukhuni 340~400HB |

| Isitimela esiyinhloko sensimbi ye-alloy, i-insert yensimbi ye-alloy, ubulukhuni obungu-38 HRC~45 HRC | ||

| Usayizi wesitimela | Ubude bezinto ezingavuthiwe | 2000~1250mm |

| Izidingo zokucubungula | Izintoubude | 1300~800mm |

| Izintoukubekezelela ubude | ±1mm | |

| Ubuso bokuphela obuqondile | <0.5mm | |

| Ububanzi bokubhoboza | φ31~i-φ60mm | |

| Ububanzi bemboboukubekezelelana | 0~0.5mm | |

| Ububanzi bokuphakama kwembobo | 60~100mm | |

| Amapharamitha obuchwepheshe ayinhloko omshini | Indlela yokusaha | Isaha elijikelezayo (isivinini esikhulu) |

| Amandla enjini ye-spindle | 37kW | |

| Ububanzi be-blade yesaha | Φ660mm | |

| Isivinini esikhulu sokuhamba se-X axis | 25m/min | |

| Isivinini esikhulu sokuhamba se-axis Z | 6m/min | |

| Uhlobo lwe-spindle yokubhoboza | I-BT50 | |

| UkubhobozaIsivinini se-spindle | 3000r/min | |

| UkubhobozaAmandla enjini ye-servo ye-spindle | 37kW | |

| Isivinini esikhulu sokuhamba se-axis X, Y, Z | 12m/min | |

| Uhlobo lwe-chamfering spindle | I-NT40 | |

| I-spindle ye-chamfering RPM Max. | 1000 | |

| Amandla enjini ye-chamfering spindle | 2.2 kW | |

| Isivinini sokuhamba kwe-axis ye-Y2 kanye ne-axis ye-Z2 | 10m/min | |

| I-chuck kagesi engapheli kagesi | 250×200×140mm(omunye200×200×140mm) | |

| Ukumunca umsebenzi | ≥250N/cm² | |

| Uhlelo lokususa ama-chip | 2isethi | |

| Uhlobo lokuthutha lwe-chip | Iketanga eliyisicaba | |

| Isivinini sokususa ama-chip | 2m/umzuzu | |

| Uhlelo lwe-CNC | I-Siemens828D | |

| Inani lezinhlelo ze-CNC | Isethi engu-2 | |

| Inani lama-axes e-CNC | 6+1axis,I-axis engu-2+1 | |

| Ukuphakama kwetafula lokusebenza | 700mm | |

| Ukuphakama kwetafula lokusebenza | cishe 37.8m×8m×3.4m |

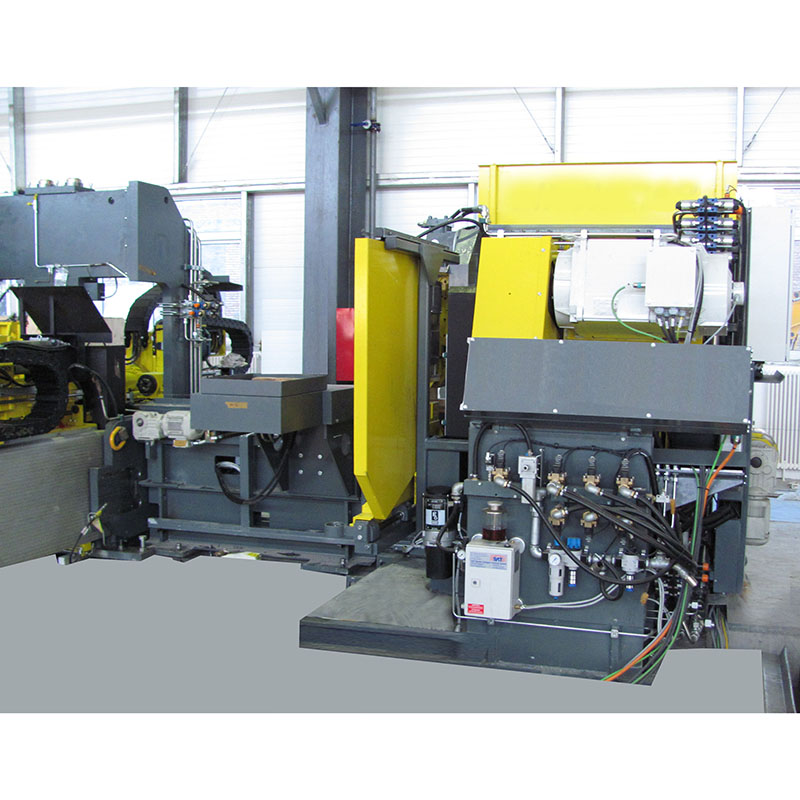

1. Kukhona idivayisi yokususa ama-chip e-blade yesaha kuyunithi yokusaha, enesibopho sokususa uthuli lwe-saw blade. Idivayisi yokupholisa nokugcoba igcoba futhi ipholise indawo yokusaha, okuthuthukisa impilo yensika yesaha. Izinsika zokuqondisa, futhi ikholomu ehambayo ifakwa embhedeni womshini.

2. Uhlelo lokubhala amakhodi

Uhlelo lokufaka amakhodi lufakwe ohlangothini lwangaphandle lwe-power head ram, futhi lufakwe ikhompyutha ephethe uhlelo nokulawula uhlelo lokufaka amakhodi.

3. Iyunithi yokubhoboza

Isakhiwo sekholomu siyamukelwa, bese ikholomu isebenzisa isakhiwo esihlanganisiwe sepuleti lensimbi. Ngemva kokwelashwa kokuguga nokufakelwa, ukuqina kokunemba kokucubungula kuyaqinisekiswa.

4. Ikhanda lokubhoboza

I-headstock yokubhoboza iyisakhiwo sohlobo lwe-ram esiqinile. Ibhande lesikhathi linamandla aphezulu okudonseka, lihlala isikhathi eside, linomsindo ophansi kanye nokudlidliza okuphansi uma lisebenza ngesivinini esikhulu. I-spindle enembile ipholile ngaphakathi futhi ingenalutho, futhi ifakwe indlela yokuxhuma uzipho olunezimbobo ezine ezingama-45°. Ingxenye yangemuva ye-spindle enembile ifakwe isilinda sokubhoboza se-hydraulic ukuze kube lula ukuyifaka esikhundleni samathuluzi.

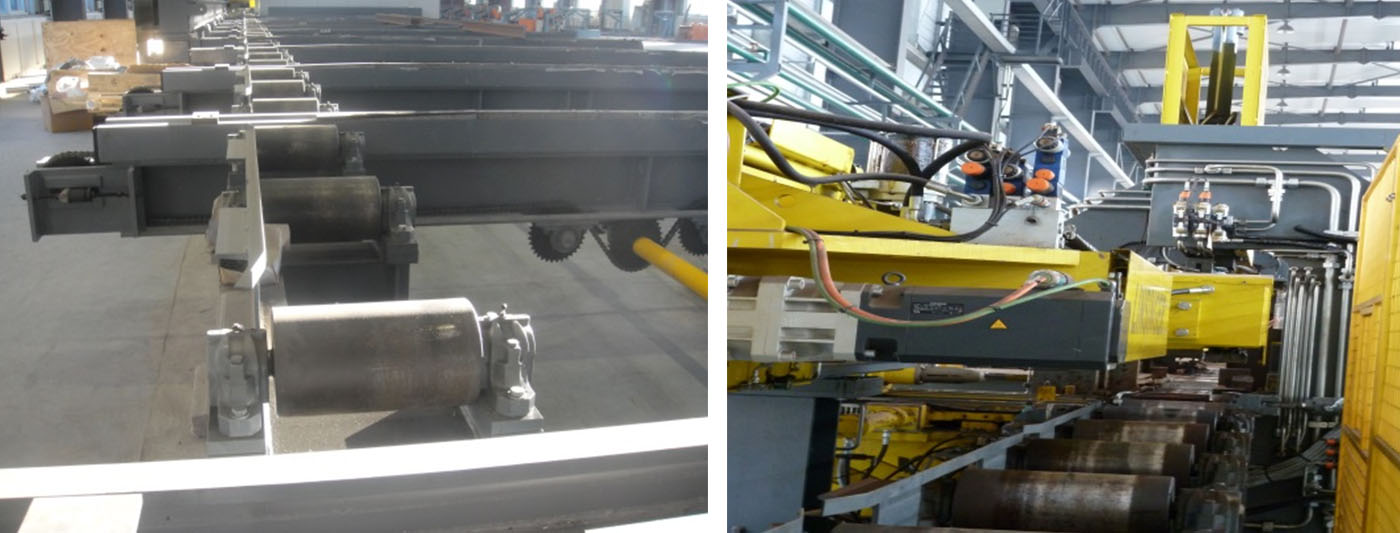

5. Ibhentshi Lokusebenza

Ibhentshi Lokusebenza lamukela isakhiwo sokushisela ipuleti lensimbi, ukwelashwa kwangaphambi kokwenziwa ngaphambi kokushisela, futhi ngemva kokushisela, impumuzo yokucindezeleka kanye nokwelashwa kokuguga okushisa kwenziwa ukuqinisekisa ukunemba nokuqina.

6. Uhlelo lokususa ama-chip

I-othomathikhi ye-chip conveyor iwuhlobo lwe-flat chain, enamasethi amabili esewonke. Isethi eyodwa isetshenziselwa iyunithi yokusaha futhi ibekwa ngaphansi kohlangothi lwe-saw blade. Enye isethi isetshenziselwa iyunithi yokubhoboza, ebekwa phakathi kombhede nebhentshi lokusebenzela. Amafayili ensimbi awela ku-chip conveyor nge-chip guide ebhentshini lokusebenzela, bese amafayili ensimbi athuthwa aye ebhokisini lokufaka insimbi ekhanda nge-chip conveyor.

7. Uhlelo lokugcoba

Kunezinhlobo ezimbili zezinhlelo zokugcoba ezizenzakalelayo ezihlanganisiwe, enye yeyunithi yokusaha kanti enye yeyunithi yokubhoboza. Uhlelo lokugcoba oluzenzakalelayo lwenza ukugcoba okungenazikhawu ku-linear rolling guide pair, i-ball screw pair, kanye ne-rack and pinion pair ukuqinisekisa ukunemba kwazo kanye nokuphila kwazo kwenkonzo.

8. Uhlelo lukagesi

Uhlelo lukagesi lusebenzisa uhlelo lokulawula izinombolo lwe-Siemens 828D, amasethi amabili esewonke, isethi eyodwa isetshenziselwa ukulawula iyunithi yokusaha, i-rack yokudla evundlile, itafula le-roll yokudla kanye netafula le-roll eliphakathi. Elinye isethi lisetshenziselwa ukulawula iyunithi yokubhoboza, ibhentshi lokusebenza 1, i-rack yokulayisha evundlile kanye nebhentshi lokusebenza.

| CHA. | Into | Umkhiqizo | Umsuka |

| 1 | Ipheya lomhlahlandlela eliqondile | I-HIWIN | I-Taiwan, iShayina |

| 2 | Uhlelo lwe-CNC 828D | I-Siemens | IJalimane |

| 3 | Sinjini ye-ervo | I-Siemens | IJalimane |

| 4 | Uhlelo lokubhala amakhodi | Iphrinta ye-LDMinkjet | IShanghai, eShayina |

| 5 | Iphampu kawoyela we-hydraulic | I-Justmark | I-Taiwan, iShayina |

| 6 | Iketanga lokuhudula | I-CPS | INingizimu Korea |

| 7 | Amagiya, ama-racks | I-APEX | I-Taiwan, iShayina |

| 8 | Isinciphisi sokunemba | I-APEX | I-Taiwan, iShayina |

| 9 | I-spindle eqondile | I-KENTURN | I-Taiwan, iShayina |

| 10 | Izingxenye zikagesi eziyinhloko | USchneider | IFrance |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba