Umshini Wokusika Isitimela we-RS25 25m CNC

| Ukucaciswa kwesitimela esicutshunguliwe | Isitimela sempahla | 43Kg/m,50Kg/m,60Kg/m,75Kg/m njll. |

| Isitimela sesigaba esingalingani | 60AT1,50AT1,60TY1,UIC33 njll.. | |

| Ubude obukhulu besitimela ngaphambi kokusikwa | 25000mm (Iingasetshenziswa futhi kuma-rails angu-10m noma angu-20m, ngomsebenzi wokulinganisa ubude bezinto zokusetshenziswa.) | |

| Ubude besitimela esisikiwe | 1800mm~25000mm | |

| Iyunithi yokusaha | Imodi yokusika | Ukusika okugobile |

| I-engeli yokusika e-Oblique | 18° | |

| okunye | uhlelo lukagesi | I-Siemens 828d |

| Imodi yokupholisa | Ukupholisa inkungu kawoyela | |

| uhlelo lokubopha | Ukubopha okuqondile nokuvundlile, okulungisekayo kwe-hydraulic | |

| Idivayisi yokondla | Inani lama-rack okondla | 7 |

| Inani lemizila engafakwa | 20 | |

| Isivinini esikhulu sokuhamba | 8m/min | |

| Ithebula le-roller lokudla | Isivinini esikhulu sokudlulisa | 25m / iminithi |

| Idivayisi yokuvala | Inani lama-blanking racks | 9 |

| Inani lemizila engafakwa | 20 | |

| Isivinini esiphezulu sokunyakaza okuseceleni | 8 m / iminithi | |

| Iyunithi yokudweba | Isivinini esiphezulu sokudweba | 30 m / iminithi |

| Uhlelo lwe-hydraulic | 6Mpa | |

| Euhlelo lwegesi | I-Siemens 828D |

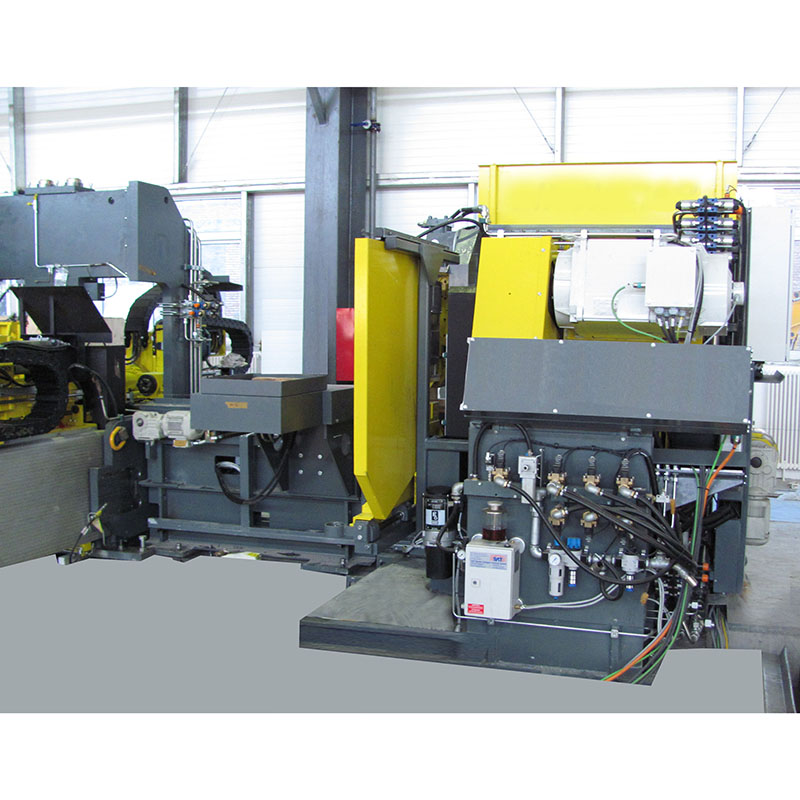

1. Idivayisi yokondla yakhiwe ngamaqembu ayi-7 ozimele bokuphakela. Isetshenziselwa ukusekela isitimela nokudonsa isitimela ukuze kucindezelwe isitimela ukuze sicutshungulwe ku-feeding rack etafuleni le-feeding roller.

2. Itafula le-roller lokulayisha lakhiwe ngamaqembu amaningana, ngalinye eliqhutshwa ngokuzimela futhi lisatshalaliswe phakathi kohlaka lokulayisha ukuze lisekele isitimela futhi lithuthe isitimela liye eyunithi yokusaha.

3. I-spindle motor ixhunywe ne-reducer ngebhande elihambisanayo, bese iqhuba ukujikeleza kokusaha. Ukunyakaza kwe-saw blade kuqondiswa ama-roller guide pair amabili aqinile aqinile abekwe embhedeni. I-servo motor iqhutshwa yi-synchronous belt kanye ne-ball screw pair, engenza i-fast forward, work forward, fast backward kanye nezinye izenzo ze-saw blade.

4. I-Inkjet iyashesha, izinhlamvu zicacile, zinhle, aziwi, azipheli. Inani eliphezulu lezinhlamvu lingu-40 ngesikhathi.

5. Kufakwe i-flat chain chip remover ngaphansi kombhede weyunithi yokusaha, okuyisakhiwo esibheke phezulu futhi sikhipha ama-iron chips akhiqizwa ngokusaha ebhokisini le-iron chip langaphandle.

6. Ifakwe idivayisi yokupholisa inkungu yamafutha okupholisa yangaphandle ukuze ipholise i-blade yesaha ukuqinisekisa ukuthi isebenza isikhathi eside. Inani lenkungu yamafutha lingalungiswa.

7. Umshini ufakwe idivayisi yokuthambisa ezenzakalelayo ephakathi, engathambisa ngokuzenzakalelayo ama-linear guide pairs, ama-ball screw pairs, njll. Qinisekisa ukuzinza komshini.

| CHA. | Igama | Umkhiqizo | Isaziso |

| 1 | Ipheya lomhlahlandlela eliqondile | I-HIWIN/PMI | I-Taiwan, iShayina |

| 2 | Uhlelo lokulawula izinombolo | I-Siemens | IJalimane |

| 3 | Injini ye-Servo kanye nomshayeli | I-Siemens | IJalimane |

| 4 | Ikhompyutha ephezulu | I-LENOVO | IShayina |

| 5 | Uhlelo lokuphrinta lwe-inkjet | I-LDM | IShayina |

| 6 | Igiya kanye ne-rack | I-APEX | I-Taiwan, iShayina |

| 7 | Isinciphisi sokunemba | I-APEX | I-Taiwan, iShayina |

| 8 | Idivayisi yokuqondanisa nge-laser | UGULA | IJalimane |

| 9 | Isikali sikamazibuthe | I-SIKO | IJalimane |

| 10 | I-valve ye-hydraulic | I-ATOS | I-Italy |

| 11 | Uhlelo lokuthambisa oluzenzakalelayo | I-HERG | I-Japan |

| 12 | Izingxenye zikagesi eziyinhloko | USchneider | IFrance |

Qaphela: Lokhu okungenhla kungumhlinzeki wethu ojwayelekile. Kungashintshwa yizingxenye zekhwalithi efanayo zomunye umkhiqizo uma umhlinzeki ongenhla engakwazi ukuhlinzeka ngezingxenye uma kwenzeka kunoma yiluphi uhlobo olukhethekile.

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba