Umshini Wokubhola we-CNC we-S8F Frame Double Spindle

| Igama lepharamitha | Iyunithi | Inani lepharamitha | ||

| Amapharamitha enqubo yohlaka | Izinto | Insimbi egoqwe ngokushisa engu-16MnL | ||

| Amandla amakhulu okudonsa | I-MPa | 1000 | ||

| Amandla Okukhiqiza | I-MPa | 700 | ||

| Ubukhulu obukhulu bokubhoboza | mm | 40(I-1965)Ibhodi enezingqimba eziningi) | ||

| Ukucubungula i-stroke | i-axis | mm | 1600 | |

| I-axis engu-Y | mm | 1200 | ||

| Ukubopha ohlangothini lweselula | i-axis | mm | 500 | |

| I-Xaxis | mm | 500 | ||

| I-spindle yokubhoboza | ubuningi | ucezu | 2 | |

| I-spindle taper | I-BT40 | |||

| Ububanzi bokubhoboza | mm | φ8~φ30 | ||

| Ibanga elincane lokubhoboza lamakhanda kagesi amabili ngesikhathi esisodwa | mm | 295 | ||

| Ukushaya kwe-feed | mm | 450 | ||

| Isivinini esijikelezayo | r/min | 50~2000(I-1965)I-Servo engenazinyathelo) | ||

| Izinga lokuphakelayo | mm/min | 0~8300 (i-Servo engenazinyathelo) | ||

| Amandla enjini ye-servo ye-spindle | kW | 2×7.5 | ||

| I-torque ekalwe nge-spindle | Nm | 150 | ||

| I-torque ye-spindle | Nm | 200 | ||

| Amandla okuphakela aphezulu okuphotha | N | 7500 | ||

| Umagazini wamathuluzi | UBUNINGI | ucezu | 2 | |

| Ifomu lesibambo | BT40 (Nge-drill ejwayelekile ye-taper shank twist) | |||

| Umthamo wamathuluzi kumagazini | ucezu | 2×4 | ||

| Uhlelo lwe-CNC | Cindlela yokulawula | Uhlelo lwe-Siemens 840D SL CNC | ||

| Inani lama-axes e-CNC | ucezu | 7+2 | ||

| Amandla enjini ye-Servo | I-Xaxis | kW | 4.3 | |

| I-axis engu-Y | 2x3.1 | |||

| I-axis ka-Z | 2x1.5 | |||

| I-Xaxis | 1.1 | |||

| I-Xaxis | 1.1 | |||

| Uhlelo lwe-hydraulic | Ingcindezi yokusebenza kwesistimu | I-MPa | 2 ~ 7 | |

| uhlelo lokupholisa | Cindlela yokupholisa | Indlela yokupholisa i-Aerosol | ||

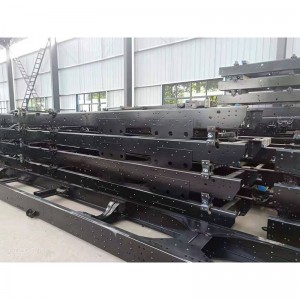

1. Umshini oyinhloko uhlanganisa kakhulu umbhede, i-gantry ehambayo, ikhanda lamandla okubhoboza (2) (lokubhoboza insimbi ejijekile ngesivinini esikhulu), indlela yokushintsha amathuluzi (2), indlela yokubeka, ukubopha kanye nokuthola, kanye netroli yokudla (2 A), uhlelo lokupholisa oluthuthukisiwe, uhlelo lwe-hydraulic, uhlelo lwe-CNC, isembozo sokuvikela nezinye izingxenye.

2. Umshini usebenzisa uhlobo lombhede oqinile kanye ne-gantry eshukumayo.

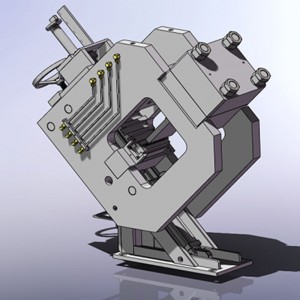

3. I-axis Y evundlile kanye ne-axis Z evundlile yamakhanda amabili kagesi okubhoboza zihamba ngokuzimela. Ukunyakaza kwe-axis Y kwekhanda ngalinye lamandla kuqhutshwa yi-screw pair ehlukile, enganqamula umugqa ophakathi wezinto; i-axis ngayinye ye-CNC iqondiswa umhlahlandlela wokugoqa oqondile. I-AC servo motor + idrayivu yesikulufu sebhola. Ikhanda lamandla linomklamo wokulwa nokushayisana ukuvimbela ikhanda lamandla ukuthi lingashayisani ngesikhathi sokusebenza okuzenzakalelayo.

4. Ikhanda lamandla okubhoboza lisebenzisa i-spindle enembile engenisiwe yesikhungo somshini wokugaya; ifakwe imbobo ye-BT40 taper, kulula ukushintsha ithuluzi futhi ingafakwa ama-drill ahlukahlukene; i-spindle iqhutshwa yi-servo spindle motor, engahlangabezana nezidingo zesivinini ezahlukahlukene kanye nemisebenzi yokushintsha amathuluzi.

5. Ukuze kuhlangatshezwane nokucutshungulwa kwezimbobo ezahlukene, umshini uhlonyiswe ngomagazini bamathuluzi abaku-inthanethi (2), futhi amakhanda amabili kagesi angaguqula ithuluzi ngokuzenzakalelayo.

6. Umshini unedivayisi yokubona ezenzakalelayo ezimele, engathola ngokuzenzakalelayo ububanzi bezinto bese ibuyisela ohlelweni lwe-CNC.

7. Uhlangothi ngalunye lombhede womshini lufakwe isethi yokulungiswa kwelaser ukuze kubekwe uhlaka ngendlela engafanele.

9. Umshini ufakwe uhlelo lwe-hydraulic, olusetshenziswa kakhulu ekubekeni nasekubopheni izinto.

10. Umshini ufakwe uhlelo lokupholisa lwe-aerosol lokubhoboza nokupholisa izinto.

11. Ugongolo lwe-gantry lomshini lufakwe isembozo sokuvikela sohlobo lwe-organ, kanti uthango lombhede lufakwe isembozo sokuvikela sohlobo lwe-telescopic steel plate.

12. Umshini usebenzisa uhlelo lokulawula izinombolo lwe-Siemens 840D SL, olungenza uhlelo lwe-CAD oluzenzakalelayo futhi lunomsebenzi wokuqashelwa kwezingqimba. Uhlelo lunganquma ngokuzenzakalelayo ibanga lokusebenza ngokuya ngobude bethuluzi (okufakwa ngesandla) kanye nokuphakama kohlaka, ngokuvamile okungu-5mm, futhi inani lalo lingabekwa ngokuya ngezimfuneko.

13. Umshini ufakwe uhlelo lokuskena oluqondile (ikhodi yebha eyodwa, ejwayelekile yokubhala ikhodi ye-CODE-128), olubiza ngokuzenzakalelayo uhlelo lokucubungula ngokuskena ikhodi yebha eqondile yohlaka ngesikena esingenantambo esiphathwa ngesandla.

14. Umshini unomsebenzi wokubala wokuqoqa ngokuzenzakalelayo inani lemigodi yokubhoboza kanye nenani lezinto ezicutshunguliwe, futhi awukwazi ukusulwa; ngaphezu kwalokho, unomsebenzi wokubala umkhiqizo, ongarekhoda inani lezinto ezicutshunguliwe uhlelo ngalunye lokucubungula, futhi ungabuzwa futhi usulwe.

| CHA. | Into | uphawu | Umsuka |

| 1 | Iziqondiso Eziqondile | I-HIWIN/PMI | I-Taiwan, iShayina |

| 2 | I-spindle eqondile | I-Kenturn | I-Taiwan, iShayina |

| 3 | Uhlelo lokuskena ibhakhodi oluqondile | ISIMBOLI | IMelika |

| 4 | Uhlelo lwe-CNC | I-Siemens 840D SL | IJalimane |

| 5 | Sinjini ye-ervo | I-Siemens | IJalimane |

| 6 | Injini ye-servo ye-spindle | I-Siemens | IJalimane |

| 7 | Izingxenye eziyinhloko ze-hydraulic | I-ATOS | I-Italy |

| 8 | Iketanga lokuhudula | IsiMisumi | IJalimane |

| 9 | Izingxenye zikagesi ezisebenzisa ugesi ophansi | USchneider | IFrance |

| 10 | Amandla | I-Siemens | IJalimane |

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba