Umshini Wokubhoboza Nokusaha Isakhiwo Sensimbi Umugqa Womshini Ohlanganisiwe

| NO | Into | Ipharamitha | ||||||||

| I-DLS400 | I-DMS700 | DI-MS1206A | DI-MS1250 | |||||||

| 1 | Ipuletiusayizi | Ukukhanya kwe-H | Iwebhuukuphakama | 100mm~400mm | 150~700mm | 150~1250mm | 150~1250mm | |||

| 2 | Ububanzi be-Flange | 75mm~300mm | 75~400mm | 75~600mm | ||||||

| 3 | Insimbi yesiteshi | Ukuphakama | 126mm~400mm | 150~700mm | 150~1250mm | 126~400mm | ||||

| 4 | Ububanzi bomlenze | 53mm~104mm | 75~200 mm | 75~300mm | 53~104mm | |||||

| 5 | Ubude obuncane bokuphakelwa okuzenzakalelayo | 1500mm | 1500mm | |||||||

| 6 | Ubude bokudla obukhulu | 12000mm | 12000mm | |||||||

| 7 | Isisindo esiphezulu | 1500kg | 1500kg | |||||||

| 8 | I-Spindle | Inani lama-headstock okubhoboza | 3 | |||||||

| 9 | Inani lama-spindle ngekhanda ngalinye lokubhoboza | 3 | ||||||||

| 10 | Uhla lokubhoboza lwezinhloko zombili | ¢12.5mm~¢30mm | 12.5~30 mm | |||||||

| 11 | Uhla lokubhoboza oluphakathi | ¢12.5mm~¢40mm | 12.5~40 mm | |||||||

| 12 | Isivinini se-spindle(I-1965)I-RPM) | 180r/min~560r/min | 20~2000r/min | 180~560 r/min | ||||||

| 13 | I-Drill clampingifomu | I-Morse No. 4 | ||||||||

| 14 | Isivinini sokuphakelwa kwe-Axial | 20mm/umzuzu-300mm/min | 20~300 mm/min | |||||||

| 15 | I-axis ye-CNC | Ukondla i-CNCAi-xis | Amandla enjini ye-Servo | 4kw | 5kW | 4kw | ||||

| 16 | Isivinini esiphezulu | 40m/min | 20m/min | 40 m/min | ||||||

| 17 | Iyunithi ephezulu ihamba ngokuvundlile | Amandla enjini ye-Servo | 1.5kw | 1.5kw | ||||||

| 18 | Isivinini esiphezulu | 10m/min | 10 m/min | |||||||

| 19 | Ukunyakaza okulungisiwe ohlangothini kanye nohlangothi oluhambayo kuqonde phezulu | Amandla enjini ye-Servo | 1.5kw | 1.5 kw | ||||||

| 20 | Isivinini esiphezulu | 10m/min | 10 m/min | |||||||

| 21 | Usayizi womsingathi | 4377x1418x2772mm | 6000×2100×3400mm | 4377x1418x2772mm | ||||||

| 22 | Isisindo somsingathi | 4300kg | 7500kg | 8500kg | 4300kg | |||||

| Amapharamitha obuchwepheshe amakhulu eyunithi yokusaha: | ||||||||||

| Ipuletiusayizi | Ubuningi | 500×400 mm | 700 ×400 mm | 1250 × 600 mm | 500×400 mm | |||||

| Okuncane kakhulu | 150 mm×75 mm | 500x 500mm | 100×75mm | |||||||

| Sawinginkemba | I-T:1.3mm | Ububanzi: 1.3mm Ububanzi: 41mm | I-T:1.6mm Ububanzi: 67mm | I-T:1.3mm Ububanzi: 41mm | ||||||

| Amandla enjini | Injini eyinhloko | 5.5 kW | 7.5 kw | 15 kw | 5.5 kw | |||||

| I-Hydraulic | 2.2kW | 2.2kw | ||||||||

| Isivinini esiqondile se-blade yesaha | 20~80 m/min | 20~80 m/min | ||||||||

| Isivinini sokudla sokusika i-blade | Ukulawula uhlelo | |||||||||

| Ukuphakama kwetafula lokusebenza | 800 mm | 800 mm | ||||||||

| NO | UBUNINGI | I-DLS400 | I-DMS700 | I-DMS1206A | I-DMS1250 |

| 1 | Isethi e-1 | Ithebula lokugoqa lokusekela lokudla | Isiteshi esiphambeneyo sohlangothi lokuphakelayo | Umbhede Wokulayisha Obanzi Wezinto Zokuphakelayo | Ithebula lokugoqa lokusekela lokudla |

| 2 | Isethi e-1 | Inqola yokondla | Ithebula le-roller lokusekela ukondla | Ama-rollers asekelayo okondlayo | Inqola yokondla |

| 3 | Isethi e-1 | Umshini wokubhoboza we-CNC onezinhlangothi ezintathu (SWZ400/9) | Inqola yokondla | I-pincher yokudla | Umshini wokubhoboza we-CNC onezinhlangothi ezintathu (SWZ1250C) |

| 4 | Isethi e-1 | Umshini wokusika ibhendi yekona (DJ500) | Umshini wokubhoboza we-BHD700 / 3 CNC 3D | Umshini wokubhoboza | Umshini wokusika ibhendi yekona (DJ1250) |

| 5 | Isethi e-1 | Ithebula lokugoqa lokusekela ukukhishwa | M1250umshini wokumaka | Umshini wokusika isaha | Ithebula lokugoqa lokusekela ukukhishwa |

| 6 | Isethi e-1 | Izinhlelo zikagesi | Umshini wokusika ibhendi ye-angle ye-DJ700 CNC | Ama-rollers asekelayo okukhiphayo | Izinhlelo zikagesi |

| 7 | Isethi e-1 | Ithebula le-roller lokusekela ukukhishwa | Uhlelo lokulawula kagesi | ||

| 8 | Isethi e-1 | Uhlelo lukagesi |

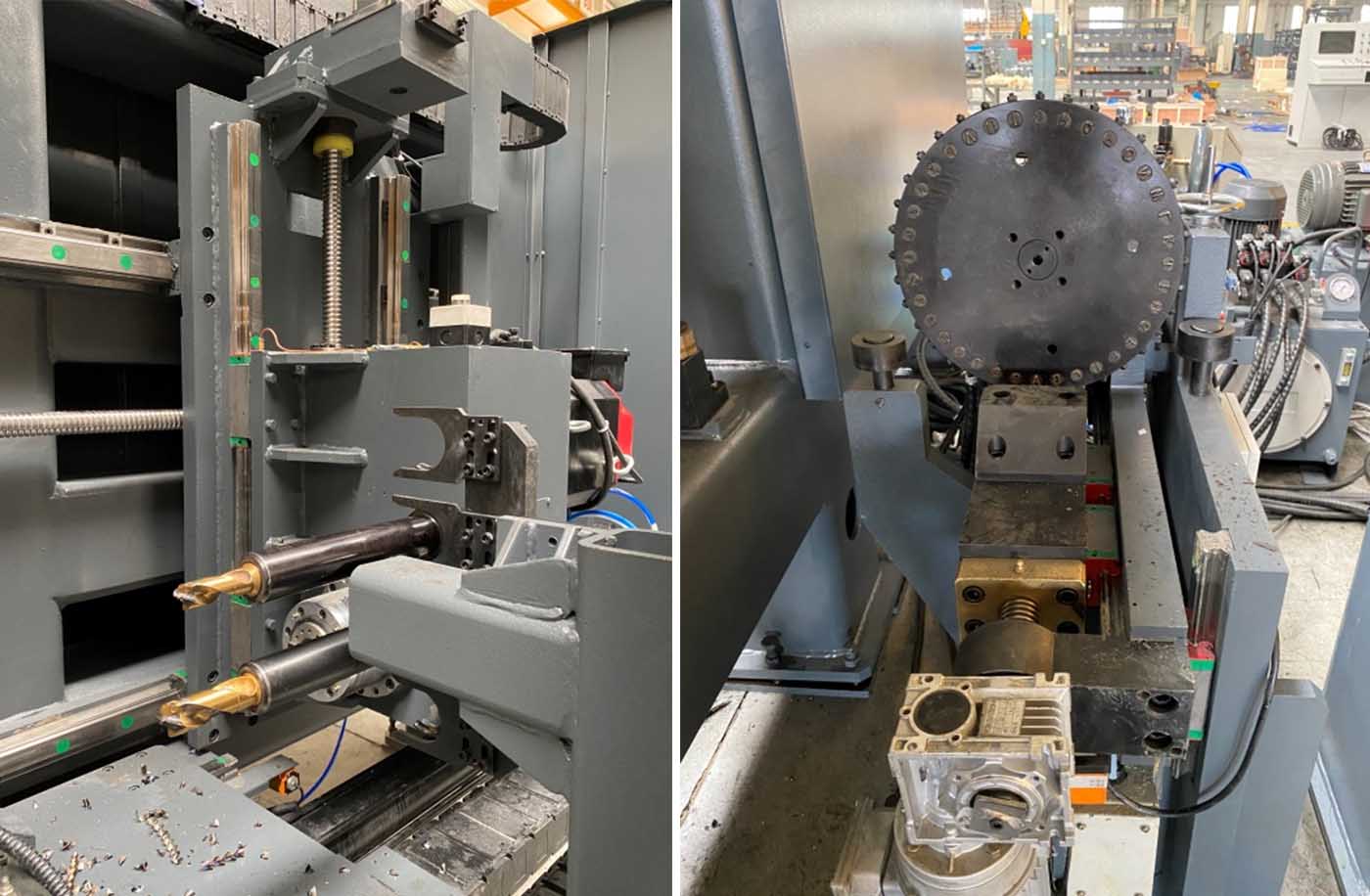

1. Umzimba Wohlaka Lomshini Oqinile Owenziwe ngepuleti lensimbi elihlanganisiwe eliqinile kanye nephrofayili yensimbi, ngemuva kwenqubo yokwelapha ukushisa eyanele, enokuqina okwanele kanye nokusebenza okuthembekile impela.

2. Ukunemba okuphezulu kokusebenza Ukunemba okuphezulu kakhulu: Ukunyakaza kwezinhlangothi ezimbili phezulu naphansi (Uhlangothi oluqondile lwe-spindle kanye nohlangothi lwe-spindle oluhambayo) kanye nokunyakaza okuvundlile kohlangothi oluphezulu, konke ukunemba okuphezulu kwe-CNC Axis ezintathu kuqinisekiswa yi-rail yomhlahlandlela oqondile womkhiqizo womhlaba wonke odumile + i-AC servo motor + i-Ball screw.

3. Idivayisi yokulinganisa ezenzakalelayo yokuphakama kwewebhu nobubanzi be-flange. Idivayisi yokulinganisa ukuphakama kwewebhu nobubanzi be-flange ezenzakalelayo ingakhokhela ukubekezelelana komsebenzi wokubhoboza uma kukhona okubangelwa ukujikijelwa okungajwayelekile kwephrofayili yezinto ezibonakalayo, okuqinisekisa ukunemba okuphezulu kokusebenza.

4. Ukunemba kwesikhundla sezinto zokudla okuphezulu Kukhona inkinobho yokugxila ye-photoelectric ku-portal yokudla yomshini, thola ngokushesha i-benchmark ekuqondisweni kokudla, ingaqinisekisa ukunemba kwesikhundla sokudla okuphezulu kakhulu ngisho nangemva kokusebenza isikhathi eside.

5. Isofthiwe yokulawula kagesi elula ethuthukisiwe Isofthiwe ingadala ngokuzenzakalelayo uhlelo lokucubungula ngokufunda ngqo umdwebo (ngefomethi echazwe), umqhubi udinga nje ukufaka usayizi wezinto ezibonakalayo, ngaphandle kohlelo oluyinkimbinkimbi, olulula kakhulu ukusebenza komshini, luthuthukisa kakhulu ukusebenza kahle kokukhiqiza.

| Cha. | Igama | Ibhendi | Izwe |

| 1 | I-PLC | Ulwazi | IShayina |

| 2 | Iziqondiso eziqondile | I-HIWIN/CSK | I-Taiwan |

| 3 | Injini ye-Servo | Ulwazi | IShayina |

| 4 | Umshayeli weseva | Ulwazi | IShayina |

| 5 | I-valve yokulawula | I-ATOS | I-Italy |

| 6 | I-valve ye-hydraulic | I-ATOS/Yuken | I-Italy |

| 7 | Iphampu ye-hydraulic | I-Justmark | I-Taiwan |

| 8 | I-valve ye-hydraulic | Yuken/Justmark | IJapan/Taiwan |

| 9 | Iziqondiso eziqondile | I-HIWIN/PMI | I-Taiwan |

| 10 | I-band saw blade | I-WIKUS/Renault | IsiJalimane/i-USA |

Iphrofayili Emfushane Yenkampani  Ulwazi Lwemboni

Ulwazi Lwemboni  Amandla Okukhiqiza Onyaka

Amandla Okukhiqiza Onyaka  Amandla Okuhweba

Amandla Okuhweba